EN

touch

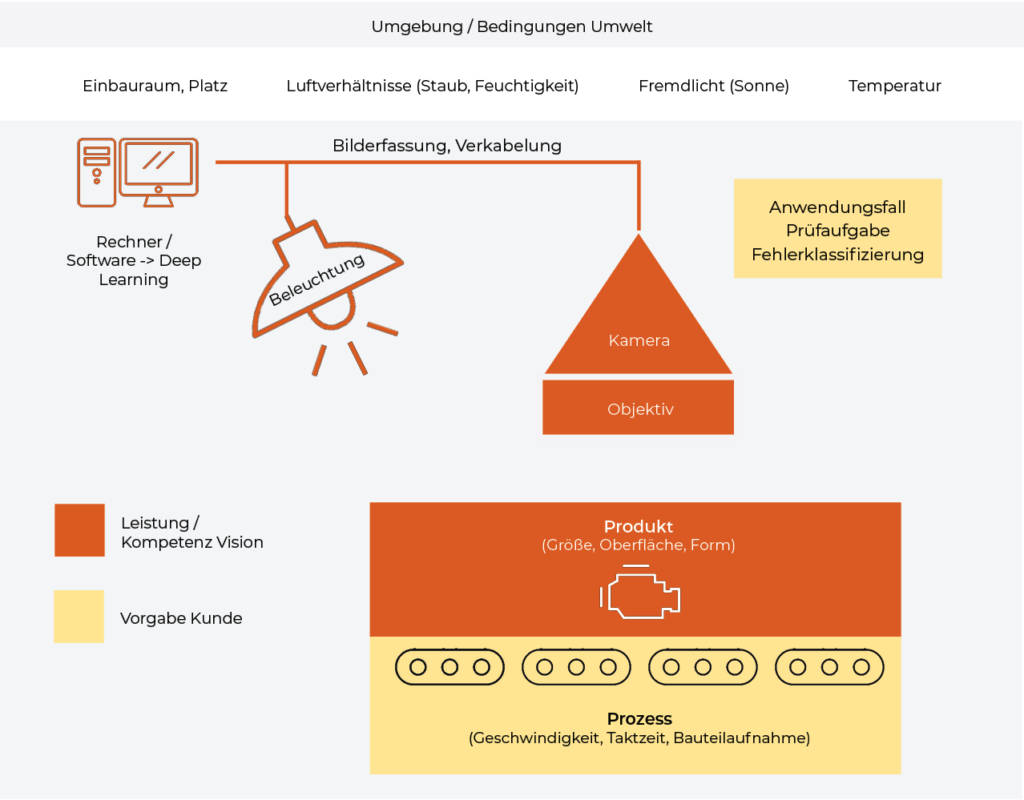

To check the visible quality features of a product, the test method of Automatic Optical Inspection, AOI for short, is especially suitable. With the help of image processing systems, errors in production are found and reported.

Possible tests in optical quality control:

Visual quality controls are still carried out manually in many production plants by trained employees using the dual control principle. However, this method involves a number of disadvantages. To err is human, as we all know. The assessment of whether a part is “good” or not is also strongly influenced by the subjective opinion of the examiner. In addition, only random samples are checked for larger production quantities. This is where machine vision solutions offer enormous advantages.

Machine vision, or industrial image processing, is the automated, digital quality assessment of test objects. The defined requirements are evaluated based on a captured image, in 2D or 3D.

Machine vision helps to perform complex industrial tasks reliably and with repeatable results.

Due to the following factors, the importance of machine vision solutions is increasing:

Efficient and high-quality: We offer you innovative systems for modern and reliable quality assurance in industrial automation. This means that errors are eliminated before they start costing money. In production, before further processing – and above all, before contact with the customer.

Customized and functional: we provide the individual basis for peak digital performance. Function-specific design, cost-efficient implementation, easy to use in everyday production. For quality assurance that is not only impressive in theory – but also in ongoing operation. We offer:

An automatic optical inspection system (AOI) has been developed to check the placement of printed circuit boards, which detects a wide range of characteristics.

Read moreWould you like to test your weld seams / spot welds automatically?

We can also support you with solutions for the optical inspection of weld seams.

Read moreAt AUTFORCE, we specialize in test systems & test bench software. Get in touch with us. Together we will find the best solution for your project!

Markus Piffer

Expert in industrial image processing

+43 (664) 966 36 38

markus.piffer@autforce.com