Insulation resistance

This test ensures that the insulation of the electric motor’s electrical components is intact. This ensures that no unwanted leakage currents occur. This helps to identify possible electrical malfunctions and safety risks.

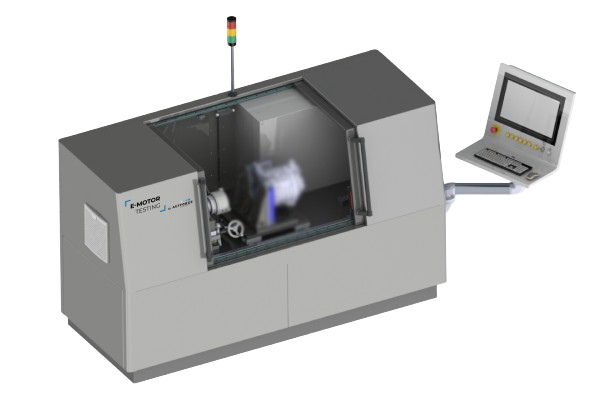

Reliable and efficient testing of electric motors with test benches from AUTFORCE

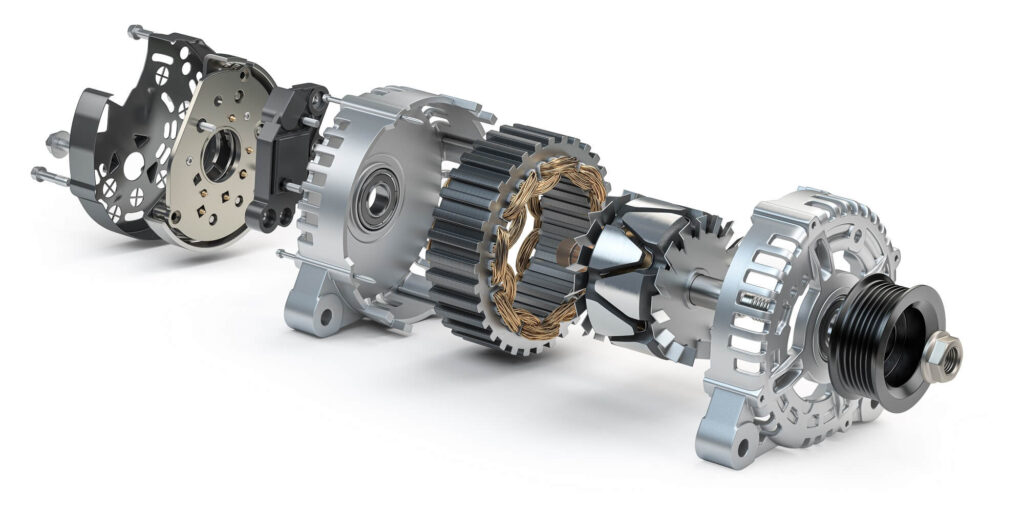

Electromobility is revolutionizing the way we get around. Electric motors are at the heart of this groundbreaking change.

The growing importance of electromobility requires not only high-performance electric motors, but also comprehensive testing to ensure the highest quality standards. Electric motors are crucial for the efficiency and reliability of electric vehicles. A thorough inspection not only ensures optimum engine performance, but also passenger safety and reduced downtime.

This new product makes it possible to perform an insulation test on stators. For temperature conditioning, the stator is placed in an oil bath in which the temperature can be varied via automation.

The tester can set an effective current and the switching frequency (PWM) via parameterization and change the edge steepness du/dt | (PWM).

By checking the total current of the stator phases, the test run can be interrupted if the insulation is damaged and the stator can be inspected for insulation damage.

A key advantage of our solution is the early identification of defects. You can be sure that potential defects or quality deviations will be detected in the early stages. This not only enables an immediate response and correction, but also leads to considerable cost savings.

Our solution enables comprehensive process optimization. You have the opportunity to continuously improve the inspection process and make it more efficient. The intelligent linking of test results with other production data creates a comprehensive database. You can make well-founded decisions based not only on individual data, but rather on a holistic analysis.

Our feasibility studies help you to ensure the viability of your concepts and to clarify open questions at an early stage. Find out more about our proof-of-concept solutions.

Easily configurable test sequence

The test sequence can be adapted with our autfactory without any programming effort. The flexibility of our software allows you to customize the testing process without having to rely on complex programming skills. This results in a smooth and efficient process that is perfectly tailored to your needs.

Connection with other production data

Our autfactory makes it possible to link the test results directly with production parameters. This not only creates transparency, but also provides valuable insights into potential returns. By analyzing related production data, patterns can be identified, causes of errors determined and preventive measures taken. This intelligent linking of information helps to increase the overall efficiency of your production and minimize downtimes.

At AUTFORCE, we specialize in test systems & test bench software. Get in touch with us. Together we will find the best solution for your project!

Christian Holzhauer

E-mobility testing expert

+49 (160) 99 08 32 68

christian.holzhauer@autforce.com

Get a non-binding initial assessment now: