Optical inspections

- 2D and 3D component measurement

- Surface inspection

- 2D and 3D stock control

- Placement control

- Color control (color value)

- OCR text recognition & code verification

- etc.

ADAM - Automatic Detection Analytics Machine

ADAM, our sorting plant & testing plant, is our solution for optimizing production processes and quality control.

The result: increased productivity and quality improvements. Our plant not only impresses with its performance, but also with its simple integration and operability, which optimizes your existing production lines and relieves employees.

Increased performance through deep learning

Our system continuously collects data during operation. This data is used to train the AI. This means that not only existing patterns are recognized, but also new shape deviations and quality features can be detected. The basis for this is a comprehensive image database.

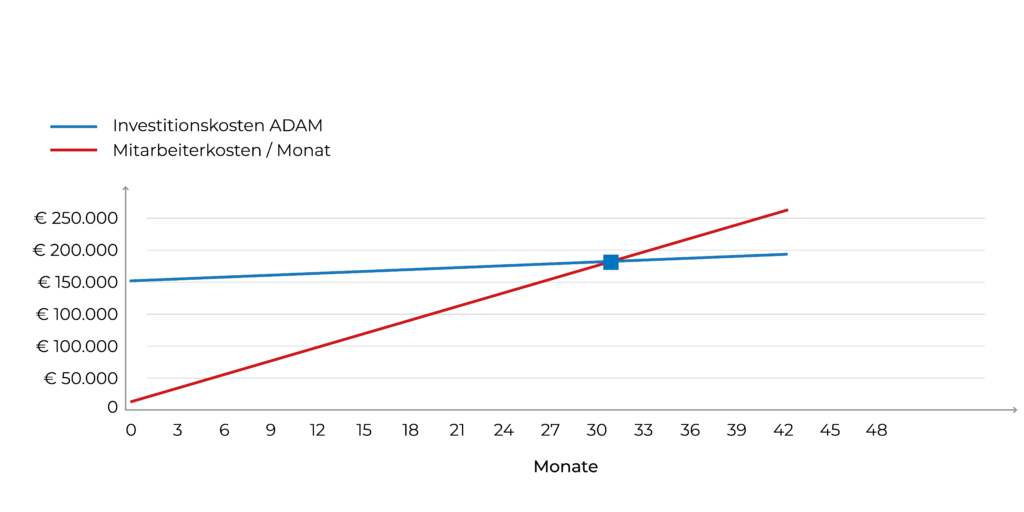

Reference project: € 150.000,-

Our testing and sorting system is suitable for high-mix low-volume (HMLV) production and is characterized by a modular system that offers maximum flexibility for a wide range of applications and components. This allows you to efficiently inspect and sort different products, from plastic parts and metal parts to precision parts, without having to make time-consuming adjustments.

Loading:

In the first step, the components are fed manually or automatically into the storage bunker. The automated inspection process is started after successful feeding.

Singling:

The components are separated using a vibrating plate, which enables the components to be separated in a targeted manner. This step ensures that each component is individually and optimally positioned for the subsequent inspection.

Testing:

The components are then tested. Both mechanical tests and camera tests (optical quality control) can be carried out. As an option, the system can be equipped with artificial intelligence through deep learning to capture even more complex quality features.

Counting & classification:

The classification of the components depends on the test results. By integrating an intelligent counting system, not only qualitative but also quantitative information can be recorded.

Sorting:

After classification, the components are sorted into appropriate storage areas. This enables smooth further processing or sorting.

With our plant, we not only offer first-class quality and efficiency, but also a clear answer to the question of return on investment (ROI).

Example for single-shift use:

Sorting and testing plants offer decisive advantages in a wide range of industries, for example in the following applications:

Before resources are invested in the full implementation, all open questions should be resolved. We test the requirements (components) on our own plant in the AUTFORCE Testlab (Proof of Concept, POC).

Our team of experts has extensive experience and the necessary equipment to carry out feasibility studies. This gives you security. POCs help to identify challenges at an early stage and to make well-founded decisions.

Find out more about our proof-of-concept solutions.

Regardless of whether you want to minimize rejects and claim costs, reduce personnel and time expenditure or avoid over- and under-deliveries – our solution helps you to reduce your costs.

Our plant eliminates capacity-related downtime and counteracts the shortage of skilled workers. ADAM ensures reliable and consistent testing. In addition, the automated test sequence guarantees comparable and reproducible results.

Human perception is subject to constant change, which leads to inconsistent results. In addition, personal interpretations are excluded by our standardized test procedures. There are clear and standardized test criteria that leave no room for subjective assessments.

The seamless integration of our test bench software autfactory into your processes enables complete digitalization of your test sequences. This creates the basis for efficient traceability and the transition to paperless production.

Configuring instead of programming

. Thanks to our autfactory, the test sequence can be easily adapted without complex programming. The flexibility of our software enables a customized design of the testing process without the need for complex programming skills.

Comply with standards & industry specifications

Our solution ensures that you can easily comply with standards and industry requirements, ensuring smooth compliance with the obligation to provide evidence. With autfactory, you are ideally equipped to succeed in the digital future of your industry.

| Size in mm LxWxH | 1900 x 910 x 1900 |

| Weight in kg without item | 350 |

| Electrical connection | CEE plug 16A (three-phase, 400V, 16A, 5-pin) |

| Interface | Ethernet |

| Security | Light grid, SIDOOR, lockable maintenance door |

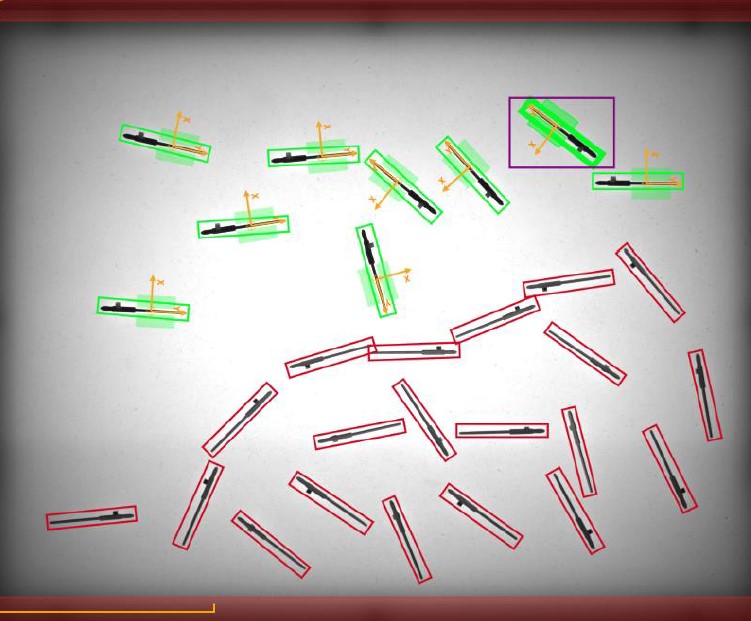

The project

We were able to implement a testing and sorting system for our customer in the medical technology sector. In this process, components are checked, classified and then sorted into separate storage containers.

Read moreAt AUTFORCE, we specialize in testing systems & industrial software. specialized Get in touch with us. Together we will find the best solution for your project!

Nick Charwat

Expert sorting systems & testing plants

+43 (664) 88 71 02 59

nick.charwat@autforce.com

Get a non-binding initial assessment now: