Prevent complaints

Automated inspection minimizes the risk of complaints due to faulty deliveries.

2D & 3D Reusable Logistics Inspection Systems

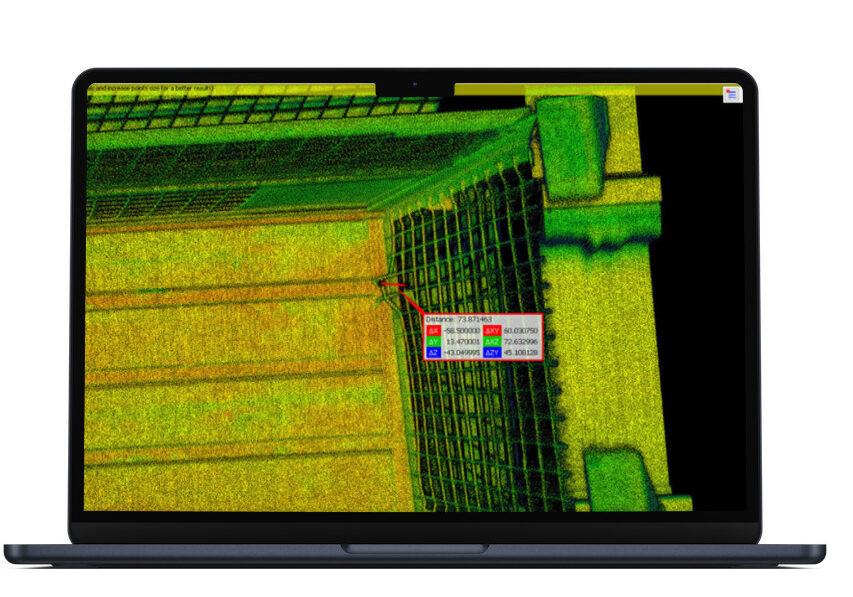

Quality inspections of products and production parts are essential in daily practice. However, reusable transport containers, such as pallets, also need to be inspected for possible damage. With our automated multi-use logistics testing plants (e.g. our PACO pallet inspection system), we can help you to automatically detect deformations and damage to transport containers using 3D sensors and camera systems.

This control is important as it can ensure automated loading with robots. Collisions between robots and reusable containers are prevented by ejecting deformed containers. As a result, costly and time-consuming downtimes are avoided. In addition, the exchange criteria for EPAL pallets in accordance with the GS1 standard and Euro pallet cages are checked.

Our inspection systems are used in production, distribution and intralogistics for a wide range of industries:

The grid boxes are checked for deformation or damage of the following areas with the help of 2D or 3D sensors:

The reusable transport containers are tested for the following characteristics:

Pallets

Grid Boxes

Plastic containers

Trays

Cartons

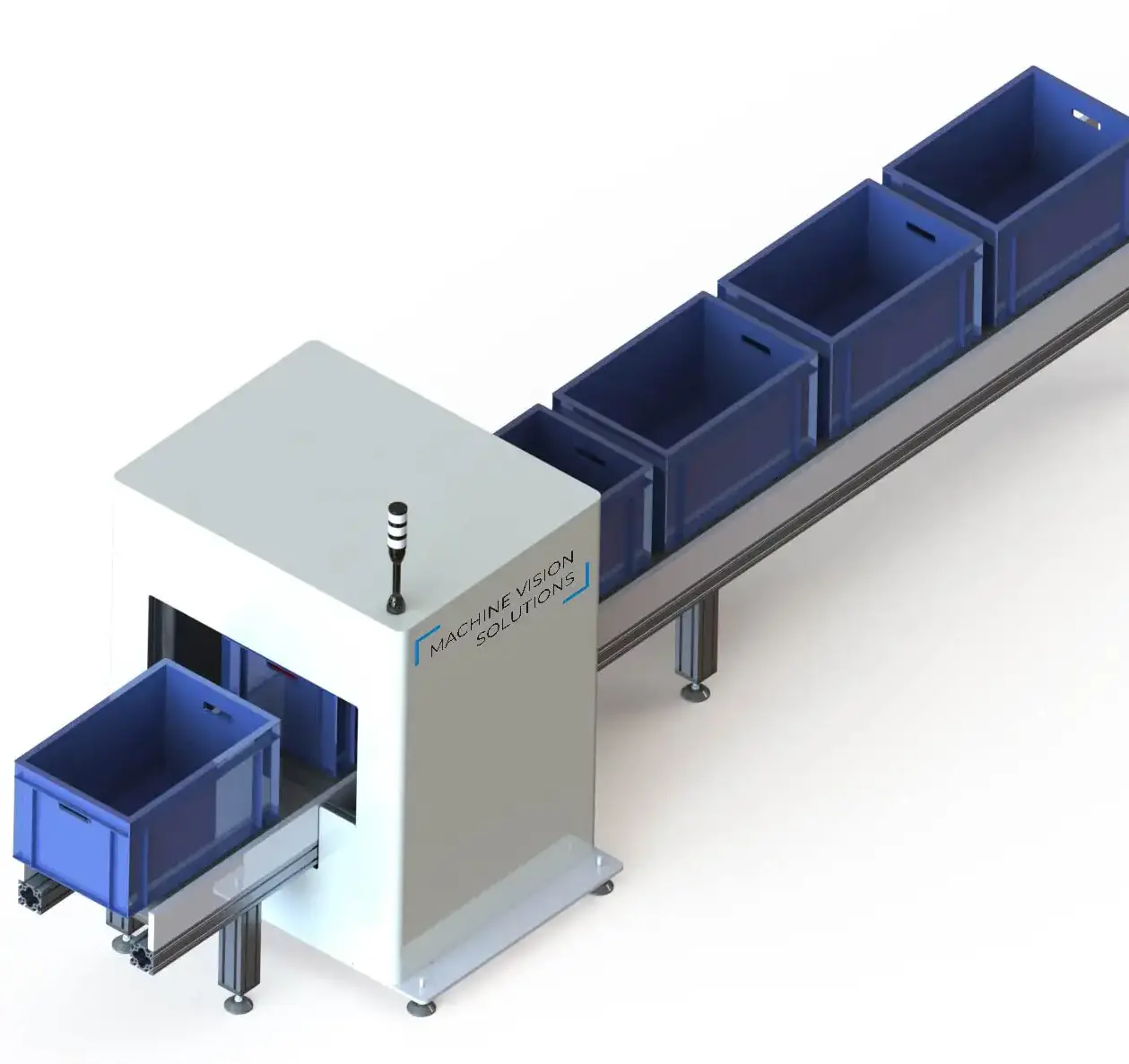

The containers are conveyed through the inspection system and scanned by 3D sensors. Depending on the requirements and the hardware used (2D/3D), up to 360 pallet cages, 400 pallets or 4,000 containers can be checked per hour.

The compact design of the testing system allows space-saving integration into your plant. A stand-alone solution is also available including pallet stackers (or magazines) and conveyor technology.

The web-based application allows the status of the plant to be viewed or parameterized at any time via the plant network.

Our autfactory test bench software provides a reliable solution for smooth data exchange between your test bench and your ERP system and offers numerous other advantages.

Reusable containers are an ecological and economical solution in the field of logistics. By reusing them, you save valuable resources and protect the environment.

Nevertheless, the effort required for handling and regular inspection of the transport containers should not be underestimated.

With our automated optical inspection systems, we help you to minimize the inspection effort and thus save costs.

Feasibility studies

Would you like to have the technical feasibility of your concept checked? Our feasibility studies provide the necessary security. Find out more about our proof-of-concept solutions.

At AUTFORCE, we specialize in test systems & test bench software. Get in touch with us. Together we will find the best solution for your project!

Markus Piffer

Expert in industrial image processing

+43 (664) 966 36 38

markus.piffer@autforce.com