Automate quality control

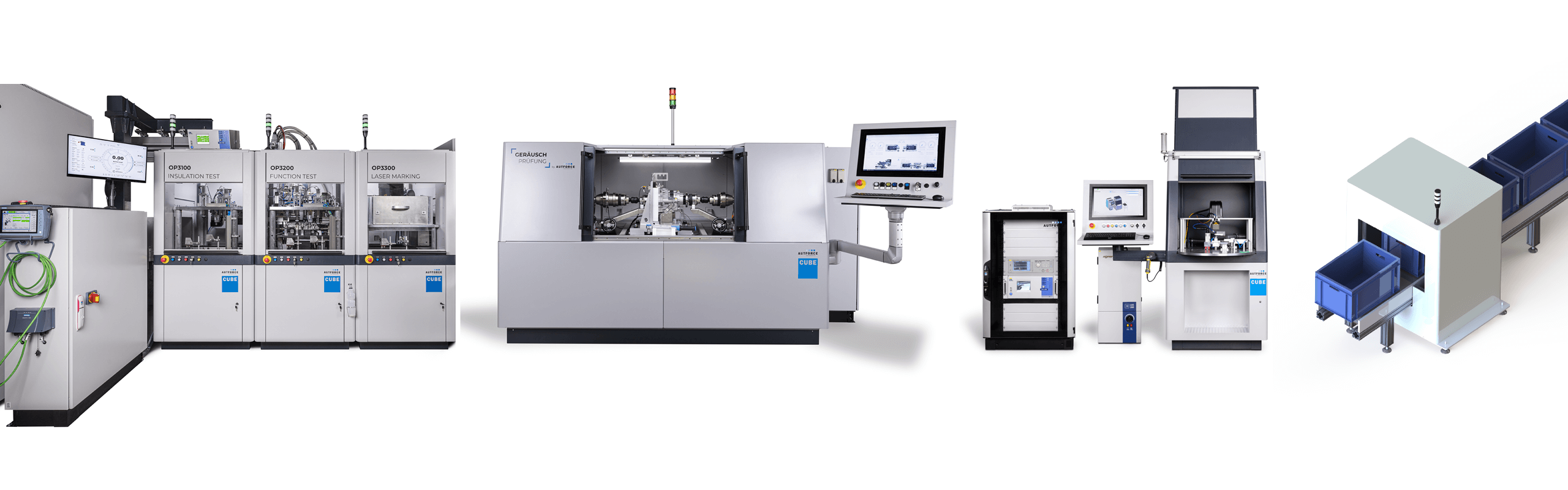

All from a single source. Let’s implement your next project together. From inverter test benches to leak test systems and vision inspection solutions. Whether as a manual workstation, cobot inspection station or rotary indexing table. Together we will find the best solution to automate your quality inspection.

Further information on the test systems