100% control with high throughput

All pallets are automatically checked and sorted, even when large quantities are involved. This ensures stable processes without bottlenecks.

Automated sorting of pallets by quality and color

Countless mixed pallet stacks often slow down day-to-day business: dirty, damaged, or mixed colors. Each pallet is visually inspected and sorted manually, which is time-consuming and physically demanding.

With our fully automated pallet sorting system, this is now a thing of the past. It separates, checks, and sorts pallets independently according to quality (EPAL-compliant) and color (e.g., CHEP, LPR) and stacks them by type.

Invest in a future with efficient pallet sorting. Maximum throughput and noticeable cost benefits.

Send an enquiry now

Automated pallet classification ensures smooth processes, greater safety, and lower costs. Flawless pallets are the basis for reliable processes in production, logistics, and trade.

In sensitive industries such as food or pharmaceuticals, only pallets in perfect condition may be used. Damaged or soiled pallets pose risks to product quality and can violate applicable industry standards.

Reliable detection of damaged or substandard pallets significantly reduces unplanned downtime, transport damage and malfunctions in automated systems. This protects personnel, reduces waste and lowers operating costs.

Color recognition enables reliable assignment of pallets from different pooling providers such as CHEP, LPR or IPP. Single-variety return becomes easier, which is particularly advantageous in FMCG, food and retail logistics.

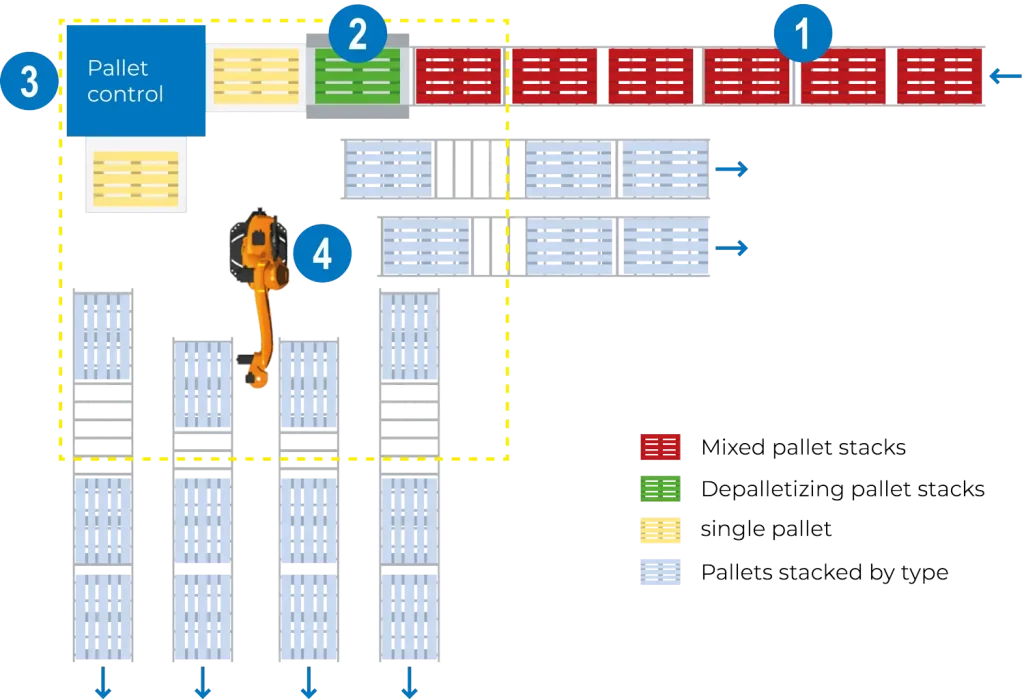

Employees transfer complete stacks to the system. The stacks are fed by pallet truck or forklift. The length of the feeding route determines the system autonomy time.

The system separates the pallets fully automatically.

The pallet control system analyzes each individual pallet using cameras and sensors. Each pallet is clearly assigned based on predefined criteria such as EPAL conformity, degree of utilization, or color coding.

The system automatically stacks all pallets according to their category. This means they are ready for your intralogistics, return or disposal.

Contact us

The layout of the pallet sorting system can be customized to suit your individual needs.

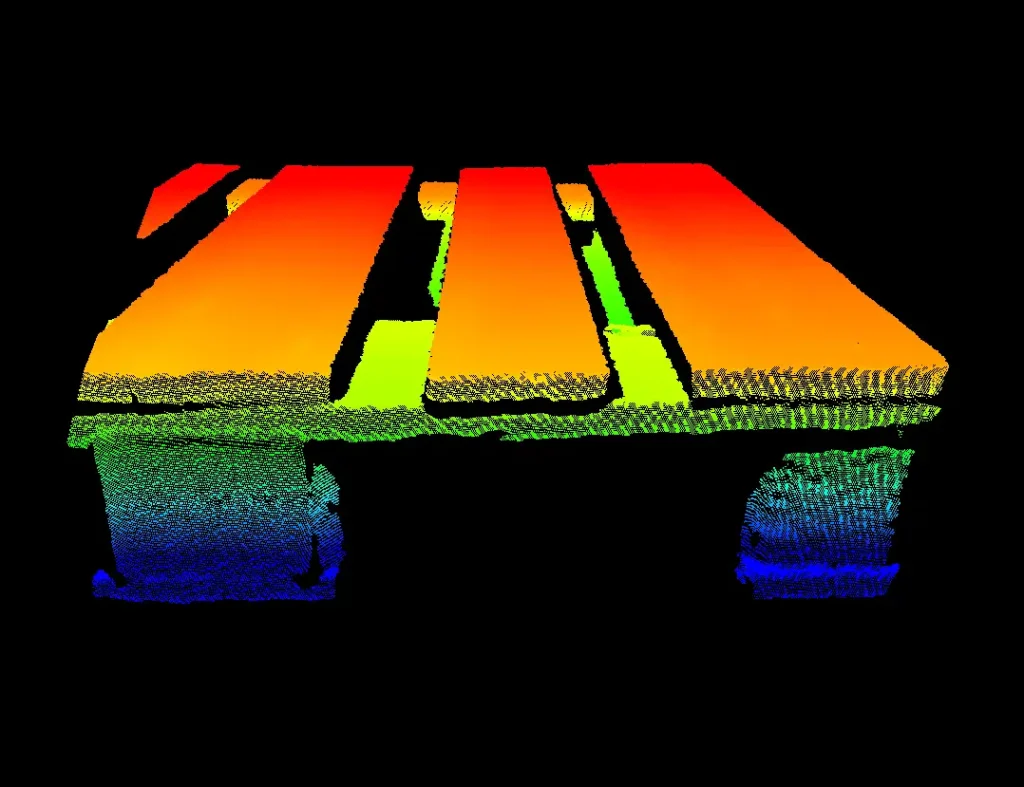

Our pallet sorting system uses the latest 3D sensor technology and industrial image processing to evaluate each pallet quickly, accurately and without contact. Our pallet inspection system (PACO) is used for this. It is an integral part of the pallet sorting system and ensures reliable and precise quality inspection.

The advantages of automated pallet inspection at a glance:

The pallet sorting system not only works efficiently, it also thinks for itself. Our industrial software autfactory records and visualizes all relevant process data in real time:

Maintain an overview at all times – whether on the Shopfloor or in the office. Whether for quality monitoring, optimization or proof to customers: autfactory provides you with all key figures at a glance – clearly structured and easy to evaluate.

Experience the system live – arrange your on-site appointment.

At AUTFORCE, we specialize in test systems & industrial software. Get in touch with us. Together we will find the best solution for your task!

Christian Hanbauer

Expert Test Systems

+43 (664) 88 71 02 50

[email protected]

Get a non-binding initial assessment now: