EN

touch

The functional test cabinet is a key component of an end-of-line test bench. During the EOL test, the inverter passes through several stations that perform processes such as insulation testing, labeling, or packaging. The functional test cabinet is the core unit that contains the control intelligence, test sequencing logic, and the required test electronics.

More flexibility for cost-effective solutions

We offer you the option of building the EOL test bench yourself and only purchasing the functional test cabinet from us. This approach provides you with a cost-efficient solution tailored precisely to your specific requirements.

The functional test cabinet can be used in various stages of the product lifecycle. From development support and validation to long-term endurance testing and final end-of-line (EOL) testing after production. You can define the required components of the functional test cabinet with us, and we will put together the required test equipment for you individually.

We provide functional test cabinets for DC link voltages ranging from 600 V to 1000 V, covering various inverter power classes and application requirements.

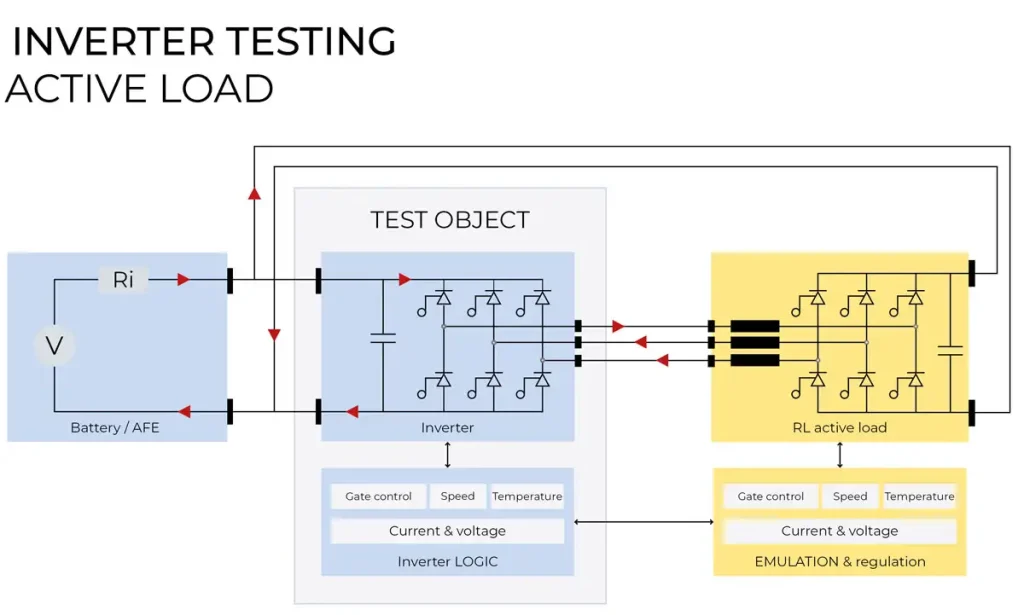

With an active load, we test the entire performance path under real conditions, enabling thorough and practical quality control.

When testing inverters, we are faced with a choice between two approaches: active load and passive load.

Let’s take a closer look at these two methods and find out which approach is best suited to your requirements.

With an active load, approximately 70–80% of all relevant inverter test cases can be covered within a single test system.

When testing inverters with an active load, real electrical power is recirculated within a closed-loop system. This means that additional power electronics are connected to the three-phase outputs (U, V, W) of the inverter, and the real power is fed back to the DC link after the AC-DC conversion, creating a closed-loop energy recovery system. Although this AC-DC conversion increases system cost due to additional power electronics, it offers some key advantages.

The obvious advantage of the active load is that it applies load to the inverter starting from the input terminals on the DC side through to the output terminals on the AC side. This is particularly important for long-term and endurance tests in order to approach the operating point of maximum power dissipation and to test the correct connection of the power electronics to the cooling circuit. Production deviations can be detected and corrected at this stage, making the active load an effective quality assurance measure. Naturally, this comprehensive test coverage requires higher system investment.

Prices & delivery times: A fully equipped functional test cabinet including active load, power supply unit, rotor position sensors and safety technology is available starting at €120,000 and is delivered within 20 weeks.

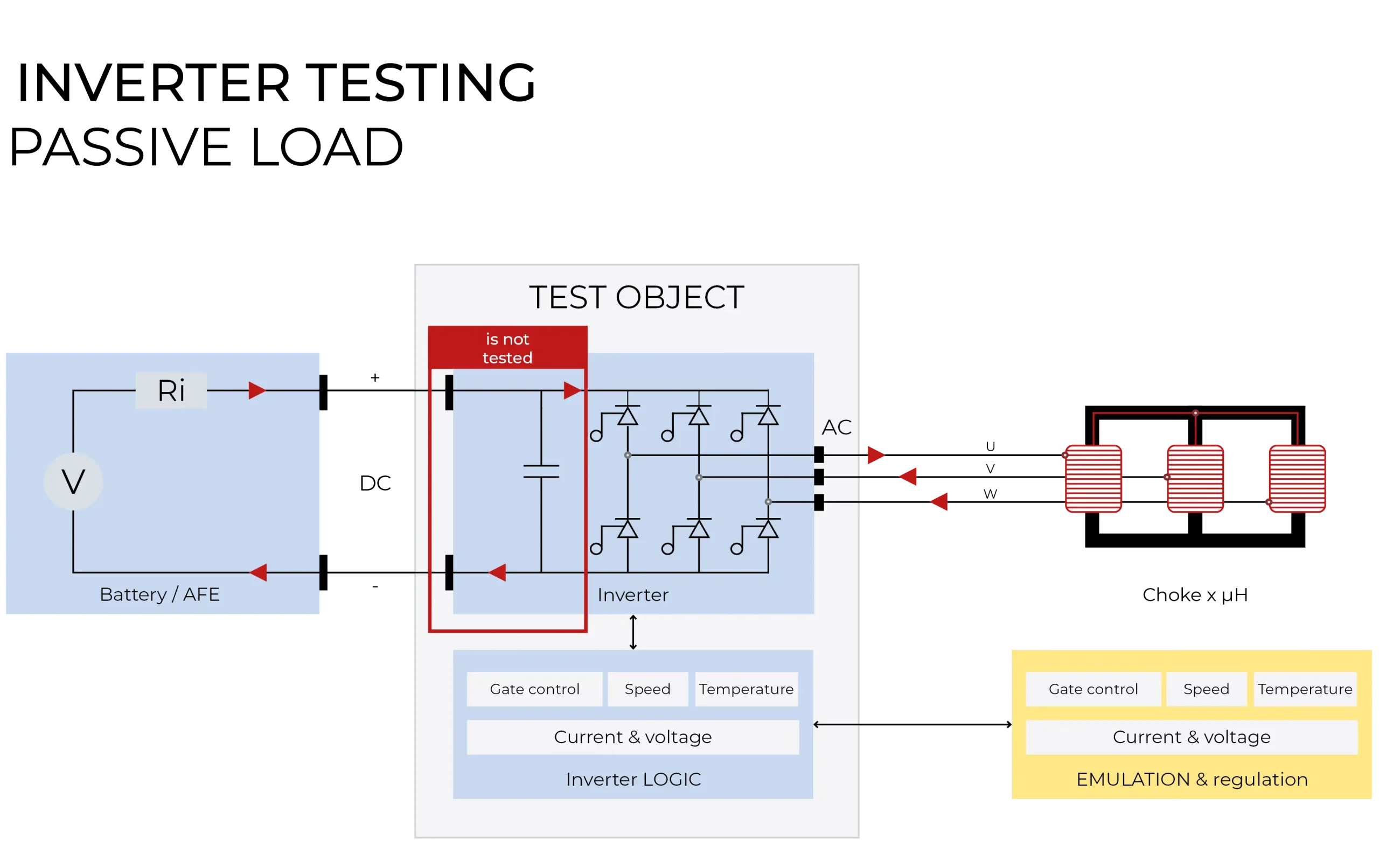

The passive load approach uses inductive loads (chokes) connected to the inverter output stages. Here, the real portion of the power is minimal, which means that the DC path is only slightly loaded. This means that the DC input path, where connection interfaces and DC terminals are also installed, is not sufficiently stressed under realistic conditions. As a result, the current levels typical for real-world applications are not achieved in this configuration. The focus is primarily on validating the functionality of the power stage rather than the complete energy path. This approach is more cost-effective and offers an interesting alternative.

Prices & delivery times: A test cabinet with passive load (inductance), power supply unit, rotor position sensors and safety technology is available starting at €75,000 and is delivered within 20 weeks.

In the end-of-line (EOL) phase, in which the correct installation of the inverter is checked, opinions differ. Some rely on EOL testers with a passive load, while others swear by 100% testing with an active load.

A balanced approach in this case would be EOL test systems with a combination of several nests of passive load and active load. This enables a cost-efficient strategy combining 100% passive testing with periodic active-load validation to ensure batch quality. For example, after 500–3,000 inverters have been passively tested, it would be conceivable to test five inverters using an active load for extended endurance testing over several days.

The AUTFORCE advantage—the consultant role

At AUTFORCE Automations GmbH, we support our customers in identifying the optimal testing strategy for their specific technical and commercial requirements.

Our strengths lie in our excellent market insight and years of experience in the industry. We understand the requirements of technical and commercial stakeholders and offer tailor-made solutions that maximize commercial benefits. When it comes to optimizing your inverter test processes, we are the right partner for you.

Feasibility studies

Would you like to have the technical feasibility of your concept checked? Our feasibility studies provide the technical and investment security you need for informed decision-making. Learn more about our proof-of-concept services.

The project

How can a 6-phase 48 V inverter be tested at the end of the production line in such a way that production peaks are absorbed and the line remains stable? This was precisely the challenge facing our customer: the existing EOL testing system had reached its limits and needed to be relieved in order to be able to cope with future peaks safely.

Read moreThe project

Little space. High quantities. No trade-offs.

How do you fit a fully automated inverter end-of-line test into an area barely larger than an average office? A customer presented AUTFORCE with this challenge – and it was as demanding as it was appealing: a high-performance test bench that could keep up with the pace of large-scale production with up to 950 inverters per shift was to be built on just 20 m².

Read moreThe project

At the request of a leading global manufacturer of drive and control technology, we were able to support the implementation of an inverter end-of-line (EOL) station. A functional test cabinet from AUTFORCE was supplied for this project. This serves as the central test control unit of the test sequences as well as the necessary measuring devices.

Read moreAt AUTFORCE, we specialize in testing systems & industrial software . Get in touch with us. Together we will find the best solution for your project!

Rainer Jung

E-mobility testing expert

+49 (160) 922 32 979

[email protected]

Get a non-binding initial assessment now: