Type recognition

Size, color, labeling & marking, etc.

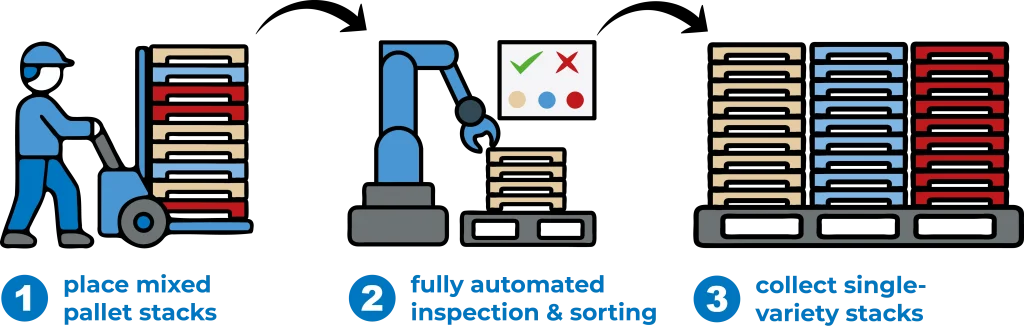

Automated sorting of pallets by quality and color

Pallets are the foundation of industrial and commercial supply chains. Manually inspecting and sorting mixed stacks of empty pallets is time-consuming, physically demanding, and dependent on individual workers.

Our fully automatic pallet sorting systems bring you noticeable cost advantages. Whether you check and sort 500 or 5,000 pallets per day, we have the right system for you.

Send an enquiry now

automatically sort empty pallets

Type | Color | Quality

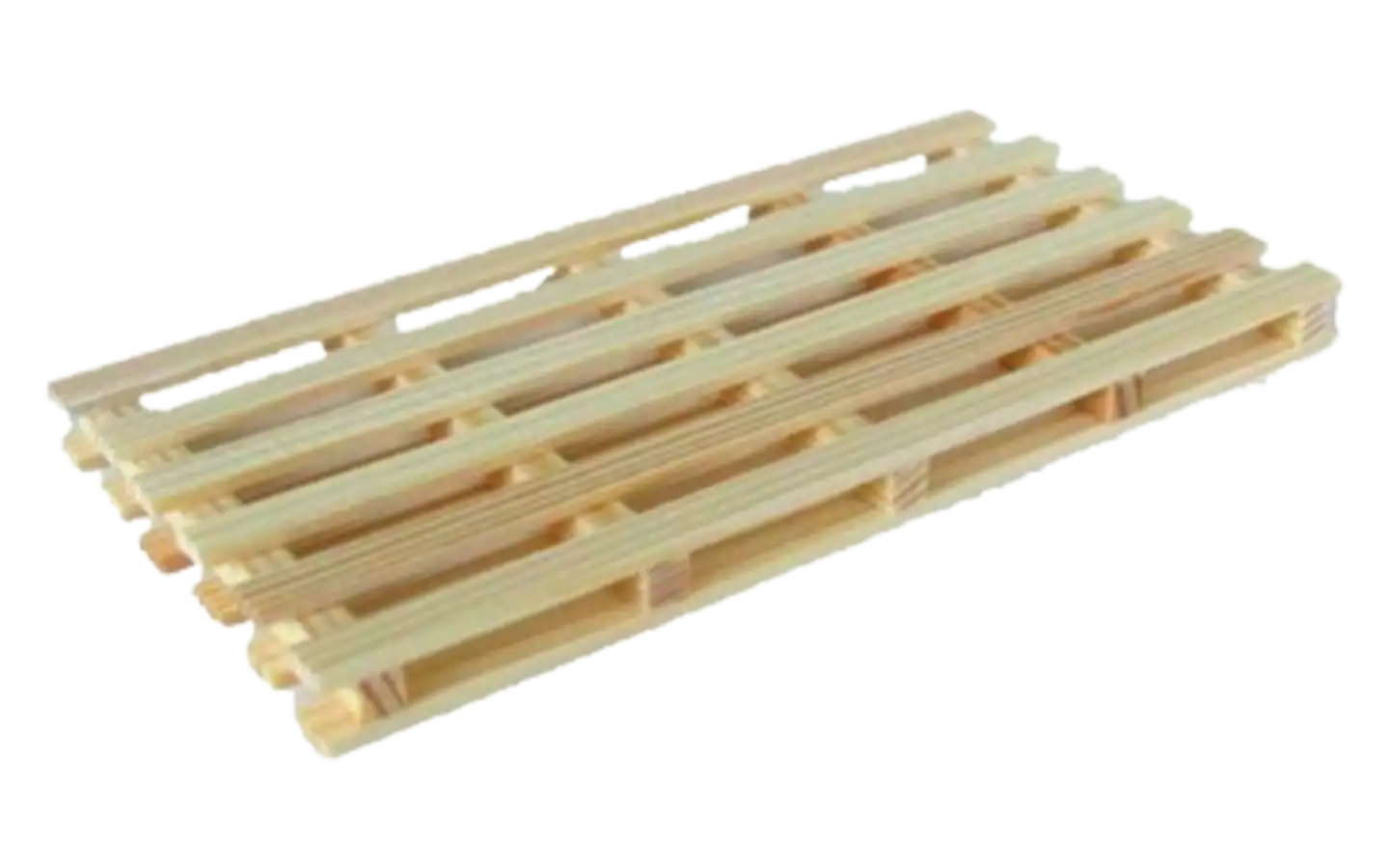

Euro pallets

CHEP pallets and other pooling pallets

Industrial pallets and FIN pallets

Düsseldorf pallets and half pallets

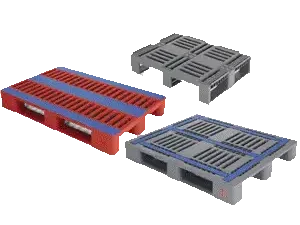

plastic pallets

Special formats (e.g., drywall pallets)

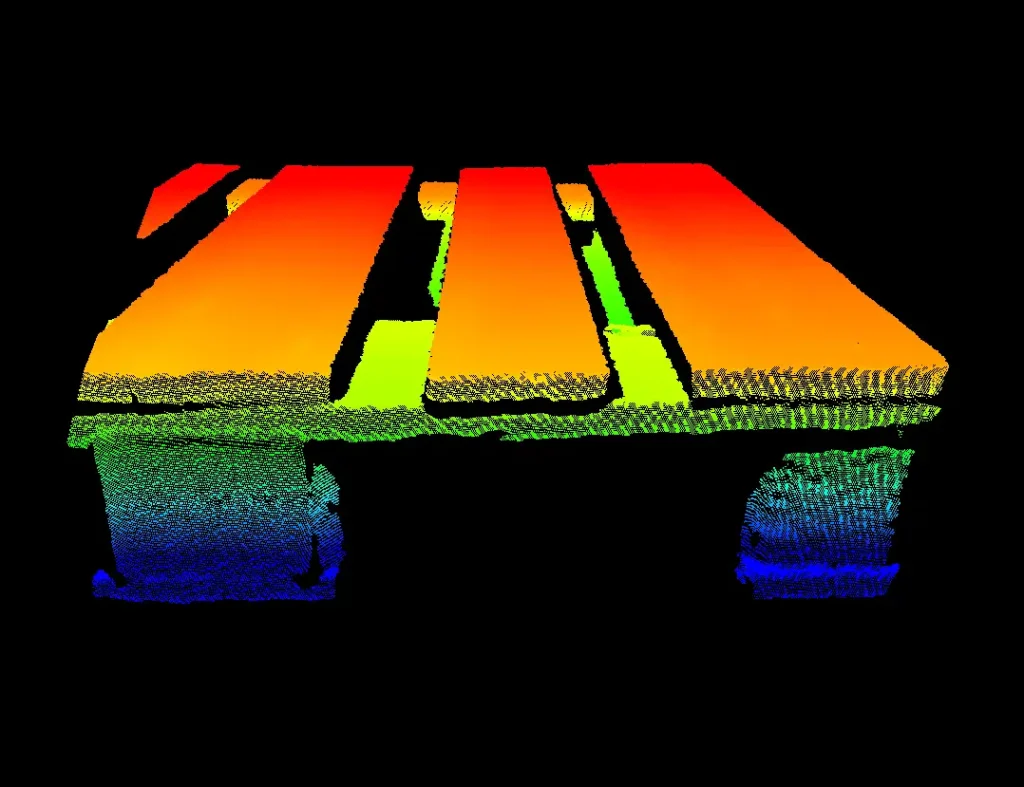

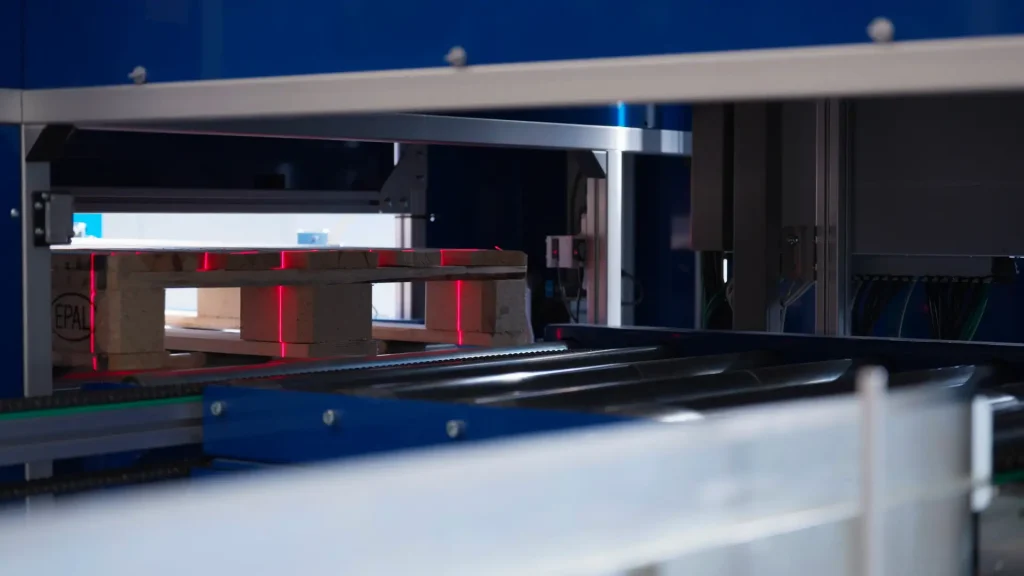

Our pallet sorting system uses state-of-the-art 2D and 3D sensor technology and industrial image processing to evaluate each pallet quickly, accurately, and without contact. This is where our pallet control system (PACO) comes into play. It is an integral part of the pallet sorting system and ensures reliable and precise quality control.

The advantages of automated pallet inspection at a glance:

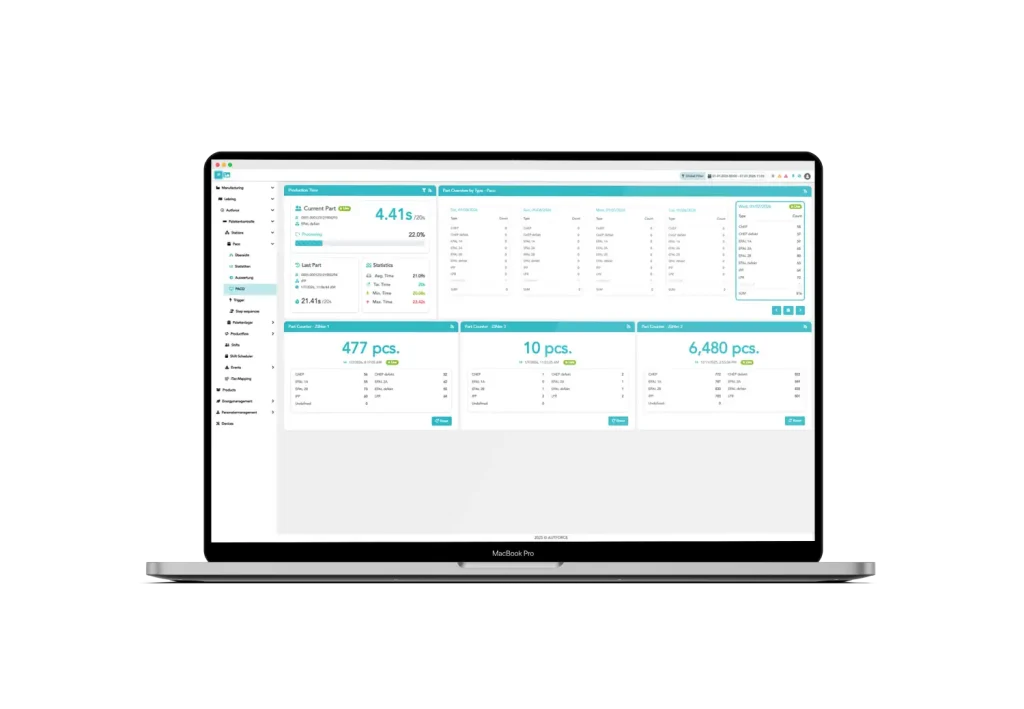

The pallet sorting system not only works efficiently, it also thinks for itself. Our industrial software autfactory records and visualizes all relevant process data in real time:

Maintain an overview at all times – whether on the Shopfloor or in the office. Whether for quality monitoring, optimization or proof to customers: autfactory provides you with all key figures at a glance – clearly structured and easy to evaluate.

Our pallet sorting system is available in various sizes. All versions check empty pallets fully automatically using 2D and 3D sensor technology and industrial image processing. Differences exist in daily throughput, installation space, investment costs, and possible autonomy time.

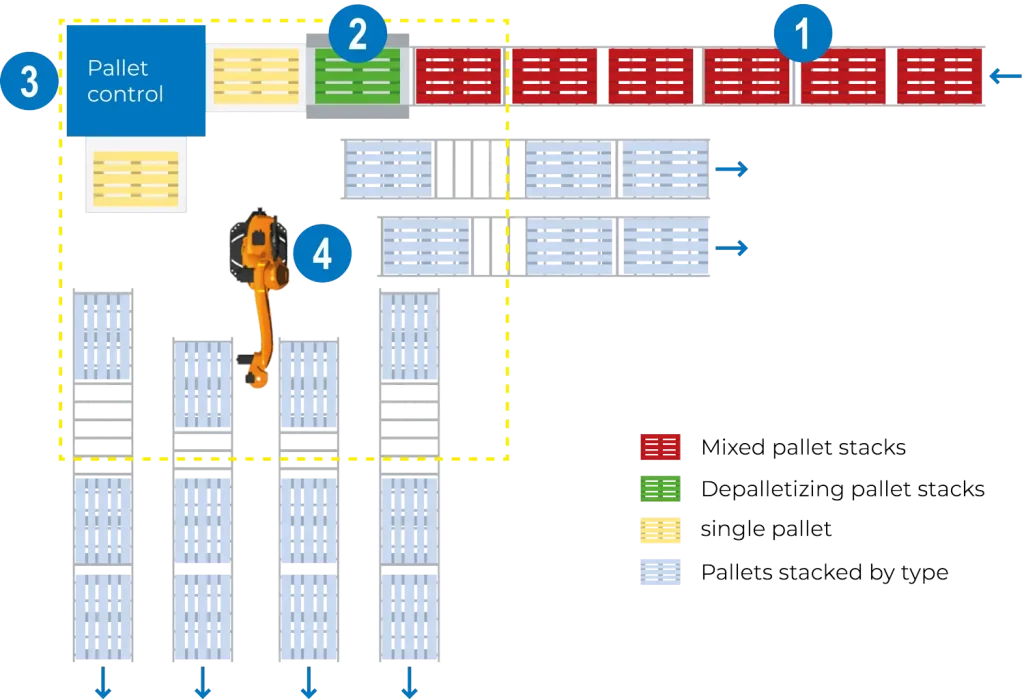

Employees transfer complete stacks to the system. The stacks are fed by pallet truck or forklift. The length of the feeding route determines the system autonomy time.

The system separates the pallets fully automatically.

The pallet control system analyzes each individual pallet using cameras and sensors. Each pallet is clearly assigned based on predefined criteria such as EPAL conformity, degree of utilization, or color coding.

Die Anlage stapelt alle Paletten automatisch nach ihrer Kategorie. So sind Sie bereit für Ihre Intralogistik, Rückführung oder Aussonderung.

Contact us

Continue to the article: Pallet inspection and sorting: The invisible heroes of logistics

Not every company wants to or can invest in the traditional way right away, and not every volume remains constant throughout the year. Our flexible procurement and usage models adapt to your needs.

Maximum control and low unit costs in the long term.

This purchase is ideal if pallet inspection is a permanent core process and high volumes are involved.

Get started quickly, conserve liquidity, and remain flexible.

Renting is suitable in the event of seasonal fluctuations or if you want to reduce investment risks.

Pay per pallet. Only pay for what you check.

Particularly attractive for uncertain or fluctuating volumes. You avoid high initial investments and only pay per inspected pallet.

Experience shows that automation potential already exists if even one of the statements applies.

Experience the system live – arrange your on-site appointment.

At AUTFORCE, we specialize in test systems & industrial software. Get in touch with us. Together we will find the best solution for your task!

Christian Hanbauer

Expert Test Systems

+43 (664) 88 71 02 50

[email protected]

Get a non-binding initial assessment now: