Ultrasonic welding of plastic components

AUTFORCE inspection and testing stations

AUTFORCE inspection and testing stations

For our customer PAYER we had the pleasure to implement an

assembly process using a collaborative robot.

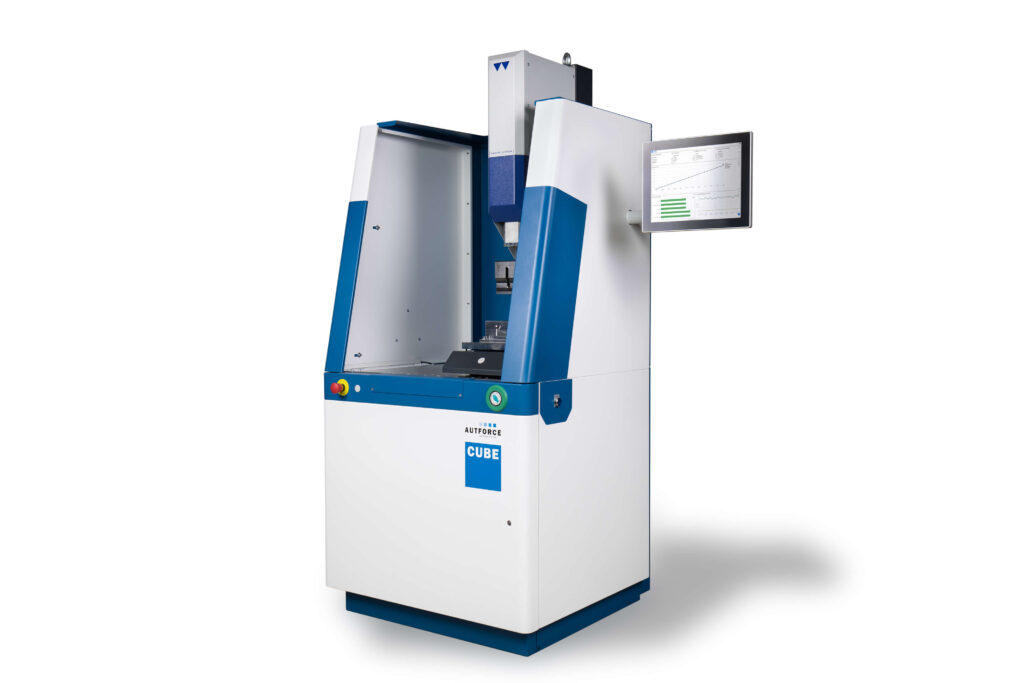

For our customer, PAYER International Technologies GmbH, we had the pleasure to realize a CUBE in connection with a Cobot. The assembly station is used to automatically insert two halves of a plastic component into the ultrasonic welding unit and then deposit them into a box. With fully loaded magazines, the robot works autonomously for around 45 minutes.

Once the robot has been loaded with the relevant magazine, it operates completely autonomously for around 45 minutes. The operator does not have to stand at the welding machine all the time and is available for other work.

The modular design makes it possible to weld different types of components. Since the robot is mounted on a separate CUBE, it can also be docked to other stations. It is als possible to use the welding station as a manual workstation.

Our customer also benefited from the completely customizable color scheme of the CUBES. The CUBES fit seamlessly into the corporate design of our client and are also a real eye-catcher in white and blue.

At AUTFORCE, we specialise in testing systems and industrial software. Get in touch with us. Together we will find the best solution for your project!

Christian Hanbauer

Test systems expert

+43 (664) 88 71 02 50

christian.hanbauer@autforce.com

Get a non-binding initial assessment now: