EN

touch

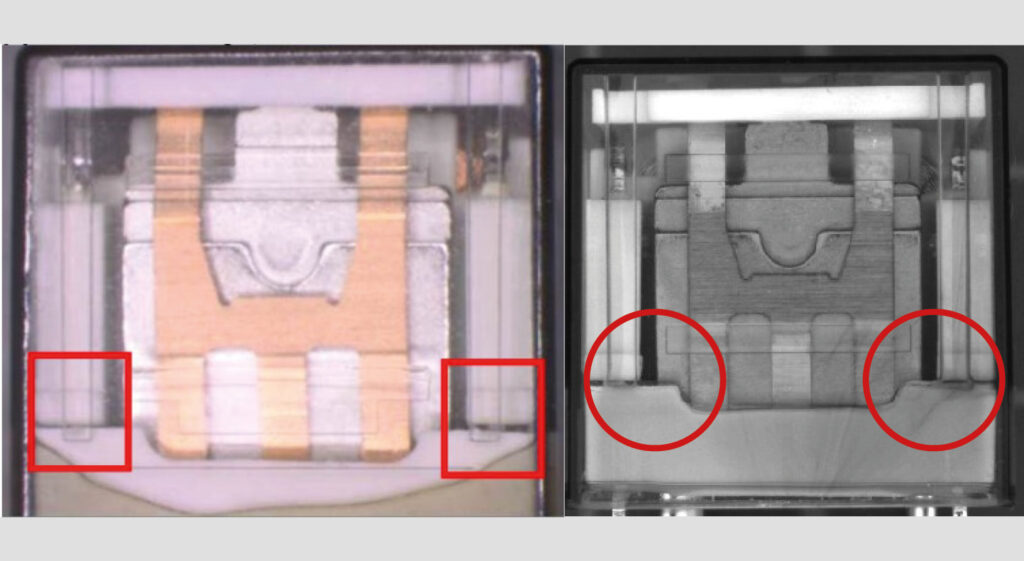

Playing it safe: We were asked to carry out a proof-of-concept study for the optical inspection of relays for our customer.

The aim of the study was to determine whether the required inspection features can be reliably detected using a camera system (industrial image processing). The experimental set-up allowed potential problems or difficulties to be identified and resolved in advance. As a result, our customer can be sure that the planned investment in an automated quality control system will pay off.

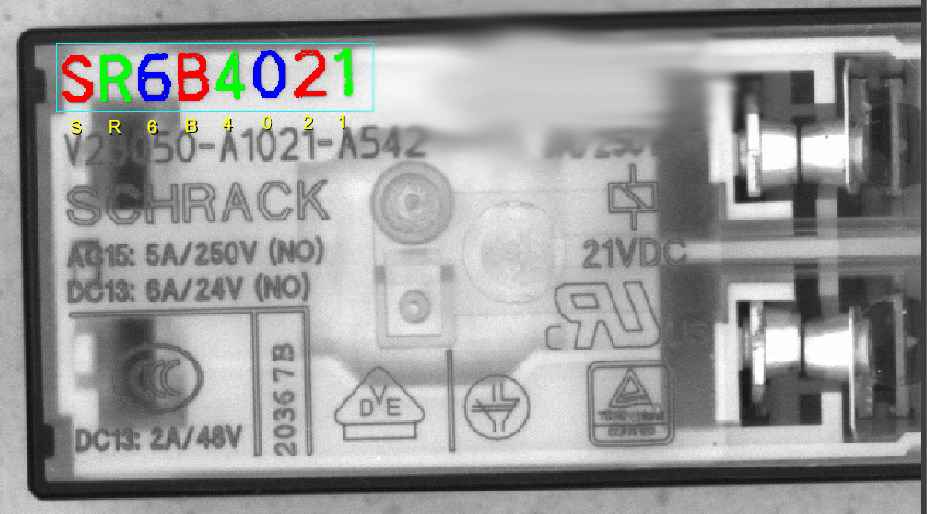

It was noted in the test setup that the labeling or imprinting of the type can be segmented and checked very well. Contrast improvements may still be possible here by using different wavelengths of light.

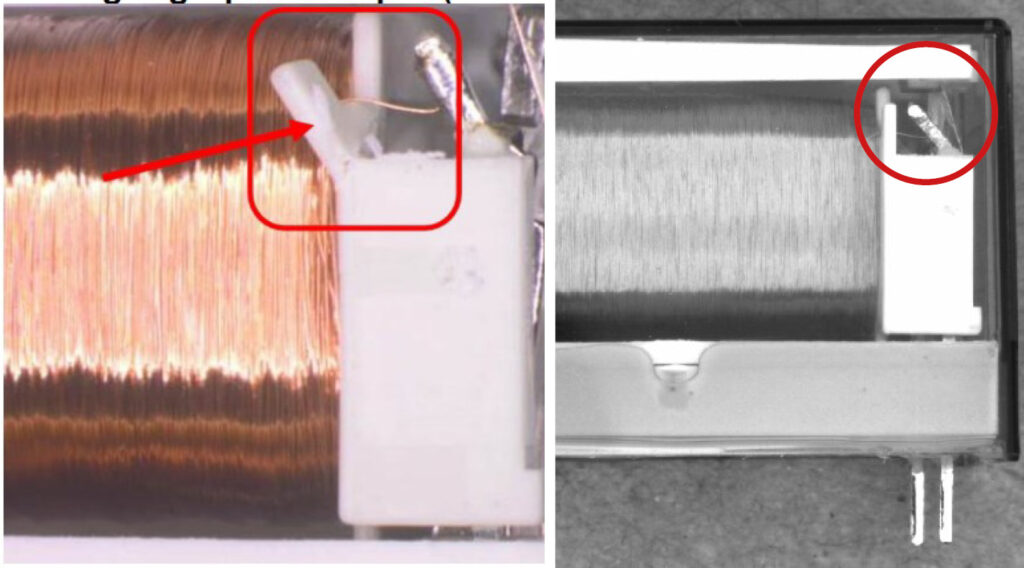

Damage to the coil bobbin can also be detected and evaluated very cleanly in the defined area due to the high contrast.

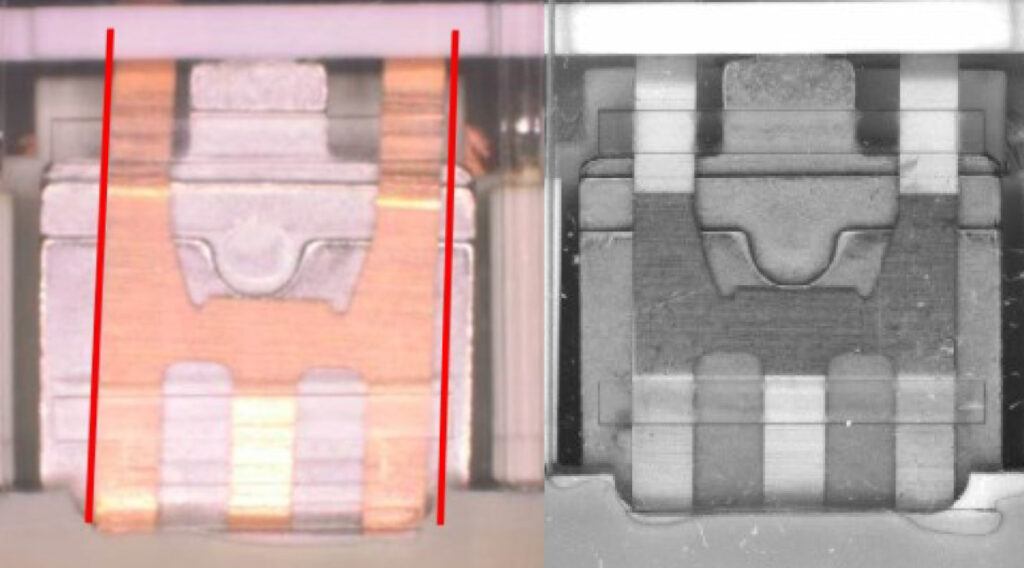

Due to the high contrast and clean edges, even skewed or bent anchor springs can be clearly detected.

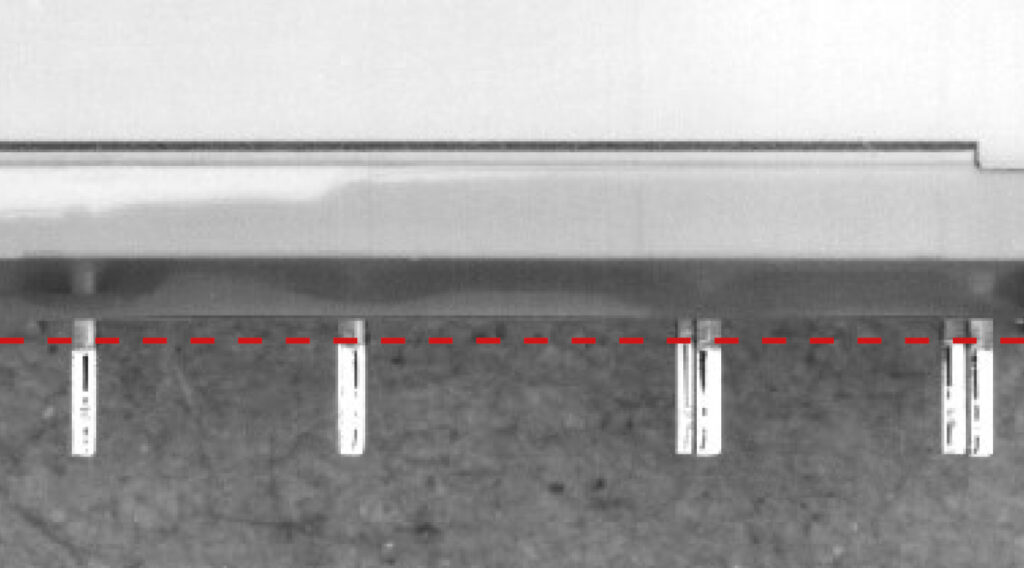

In addition, the level of tinning was inspected. This must be at least 0.5 mm above the contact area, and is very easy to see.

The distances between the upper and lower parts are very easy to see. The resolution of the camera could possibly be adjusted if the tolerances or measured values are very low.

At AUTFORCE, we specialize in test systems & test bench software. Get in touch with us. Together we will find the best solution for your project!

Markus Piffer

Expert in industrial image processing

+43 (664) 966 36 38

markus.piffer@autforce.com