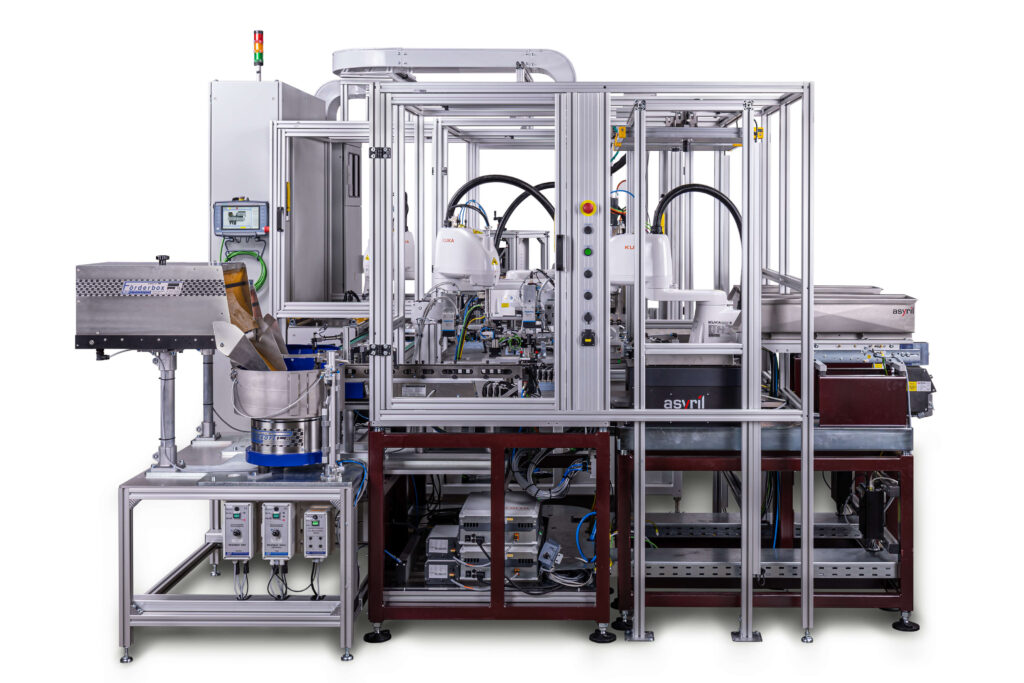

Space-saving

Thanks to the compact, ergonomic design, the available space was used in the best possible way.

Individual Systems by AUTFORCE

We were able to demonstrate our expertise in the field of customized systems with a winding system for copper coils.

An existing winding plant for copper coils was integrated into a new, digitally connected plant. The aim of the project was to convert the existing plant so that it could be used for the production of different types of magnetic coils. The coils are transferred to further process steps and undergo optical quality control after being resistance welded. It was particularly important for us to make the best possible use of the existing equipment and to implement an optimal automation solution on the available production area.

Our services ranged from the mechanical design to the mechanical construction, the risk analysis, the electrical planning, the control cabinet construction, the electrical installation, the control programming, as well as the supply of the hardware.

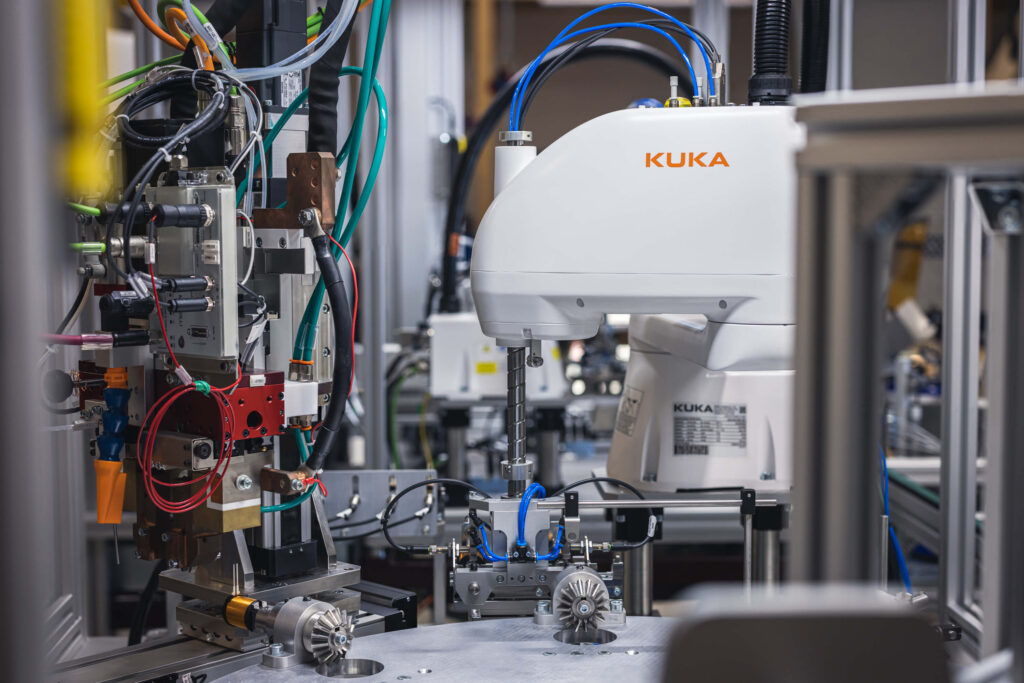

The robot removes the coils wound by the winding machine and places them in a transfer nest by using a double gripper. This transfer nest then loads the rotary indexing table.

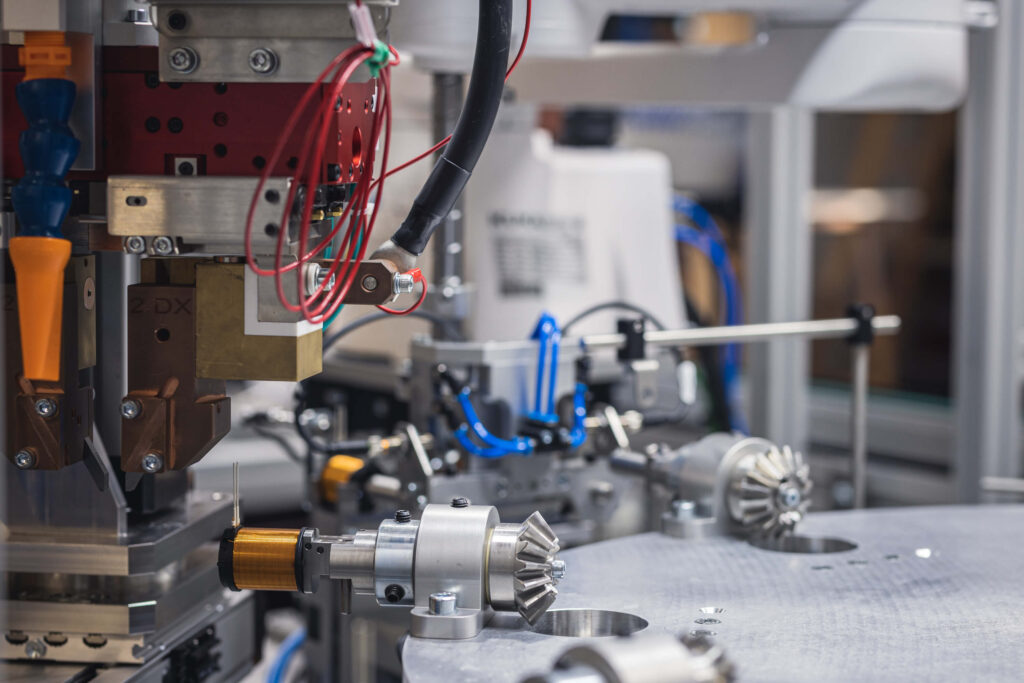

At the rotary indexing table, the contacts of the coilformers are welded with a welding head.

Am Rundtakttisch werden die Kontakte der Spulenkörper mit einem Schweißkopf verschweißt. The welding contacts are then checked for accuracy and quality by two Keyence cameras.

In the next step, the coil formers are removed from the rotary indexing table via a transfer nest and then deposited in the IO or NIO rack via robot. The removal of the horde is done by a conveyor belt.

At AUTFORCE, we specialise in testing systems and industrial software. Get in touch with us. Together we will find the best solution for your project!

Christian Hanbauer

Expert Test Systems

+43 (664) 88 71 02 50

[email protected]

Get a non-binding initial assessment now: