No waiting times

The system picks your orders overnight.

From goods receipt to order picking ready for shipment—a smart system for small and medium-sized items

When hundreds of small items such as contact lenses, glasses, or similar products arrive at the warehouse every day, manual processes quickly reach their limits. Sorting and picking takes time and ties up staff.

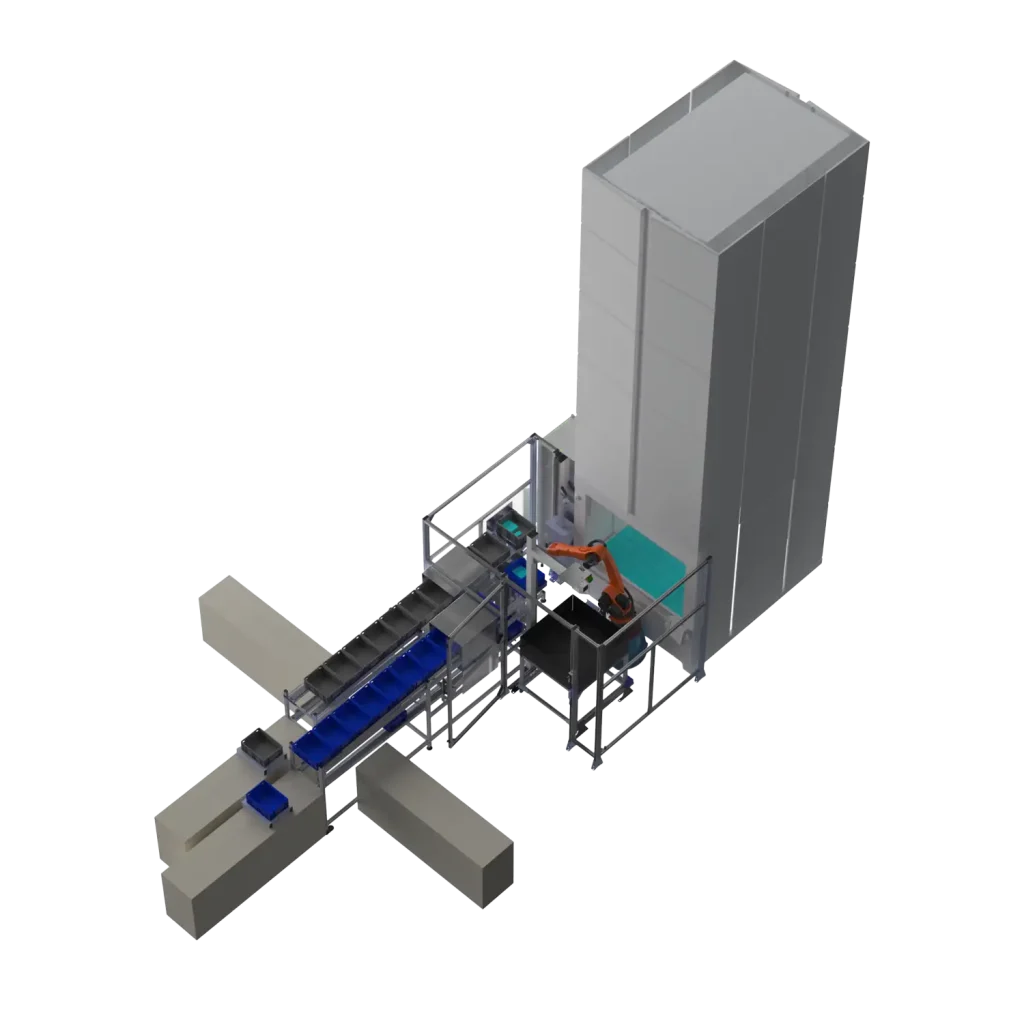

Our automated small parts warehouse handles the entire material flow: packages are separated, recorded, checked for damage if necessary, stored in a space-saving manner, and made available for shipping directly if required. This ensures stable processes, fewer errors, and consistently high efficiency, even with increasing quantities. As a result, your employees gain time for more value-adding activities.

Learn more

Ideal for high diversity and limited space!

In modern fulfillment and logistics processes, a wide variety of items and packaging sizes arrive at the central warehouse every day.

Manual sorting and storage are time-consuming, error-prone, and expensive.

For small items in particular, this means high personnel costs, limited scalability, and increased costs per order.

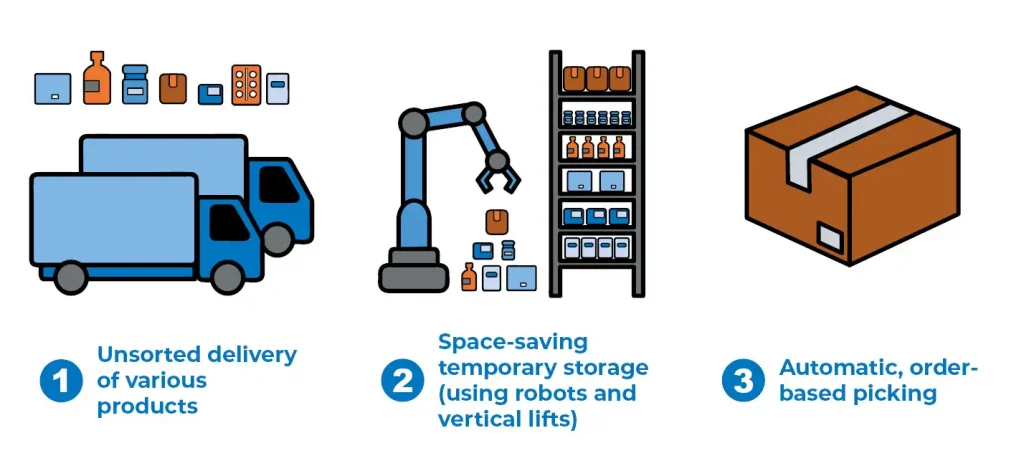

From unsorted delivery to customer order ready for shipping in 4 steps.

Incoming packages and small items are fed into the system unsorted as bulk goods. This enables flexible and fast handling of a wide variety of item sizes and shapes without prior manual sorting.

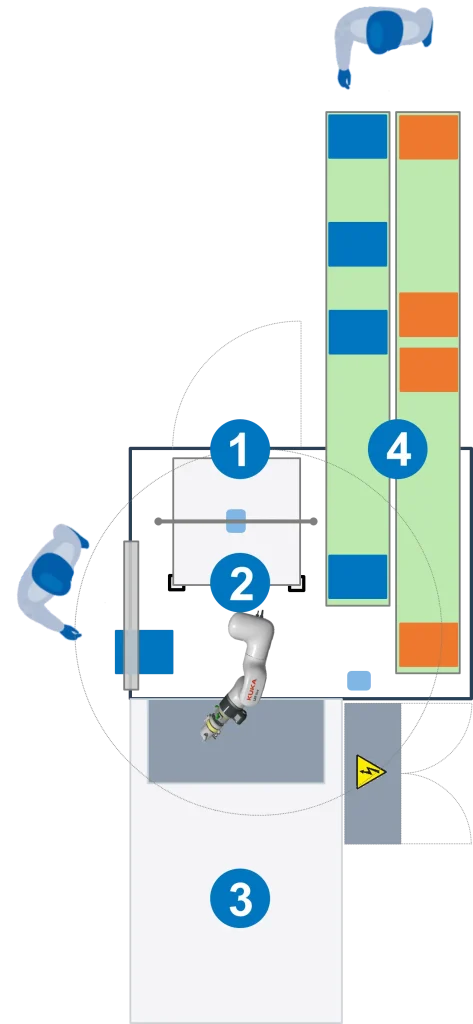

A camera-based robot system recognizes each individual package, picks it up precisely, and automatically separates the items. In this step, our system checks the packaging for integrity, abnormalities, and damage as needed.

At the same time, the barcode of each package is recorded and transmitted to the integrated warehouse management system or a higher-level warehouse management system (WMS). This means that every item is uniquely identified, traceable, and quality-checked right from the start—without any manual intervention.

The scanned items are automatically stored in a space-saving vertical lift. This ensures optimal use of the available space and guarantees the safety of the goods.

The system picks your orders fully automatically using robots. Even at night and completely without personnel involvement (e.g., unmanned shift).

Contact us

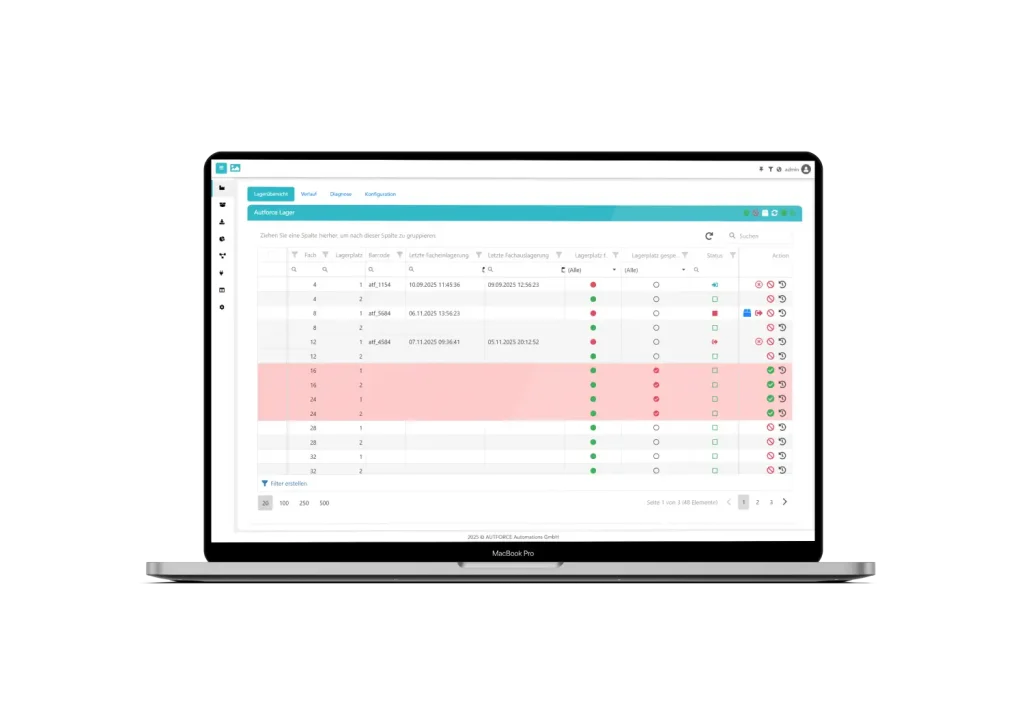

Thanks to the integrated warehouse management software autfactory, the system operates completely autonomously and can be seamlessly integrated into your existing ERP, WMS, or MES environment as needed. This allows you to maintain an overview of inventories, orders, and material flows at all times.

At AUTFORCE, we specialise in testing systems and industrial software. Get in touch with us. Together we will find the best solution for your task!

Christian Hanbauer

Expert Test Systems

+43 (664) 88 71 02 50

[email protected]

Get a non-binding initial assessment now: