EN

touch

A new generation of quality assurance for tank caps:

More efficient, more powerful, more user-friendly!

New plant technologies or further developments for the continuous improvement of existing technologies promise noticeable progress for industrial production. The integration of such a new technological generation with its numerous advantages is a must for the industry to be carried out as soon as possible, but at the same time it poses a multitude of challenges for both machine builders and programmers.

It is essential to carry out the respective adaptation precisely and with the utmost care – in addition to the actual task of realizing a compact, fully functional plant in a timely and trouble-free manner. Autforce has accepted this challenge together with Dynamic Assembly Machines Slovakia!

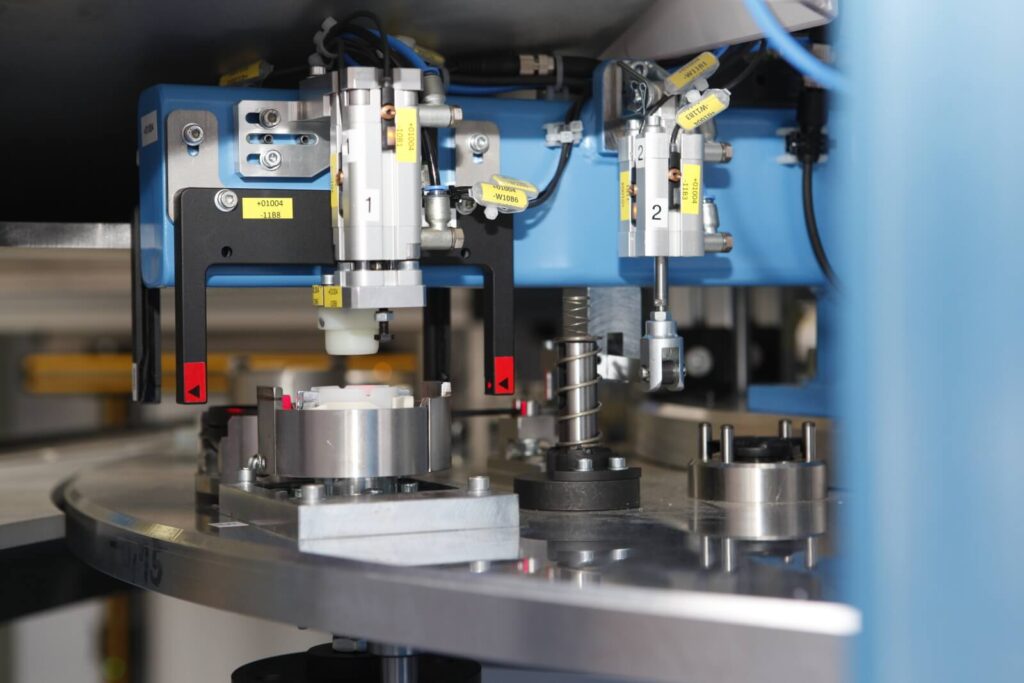

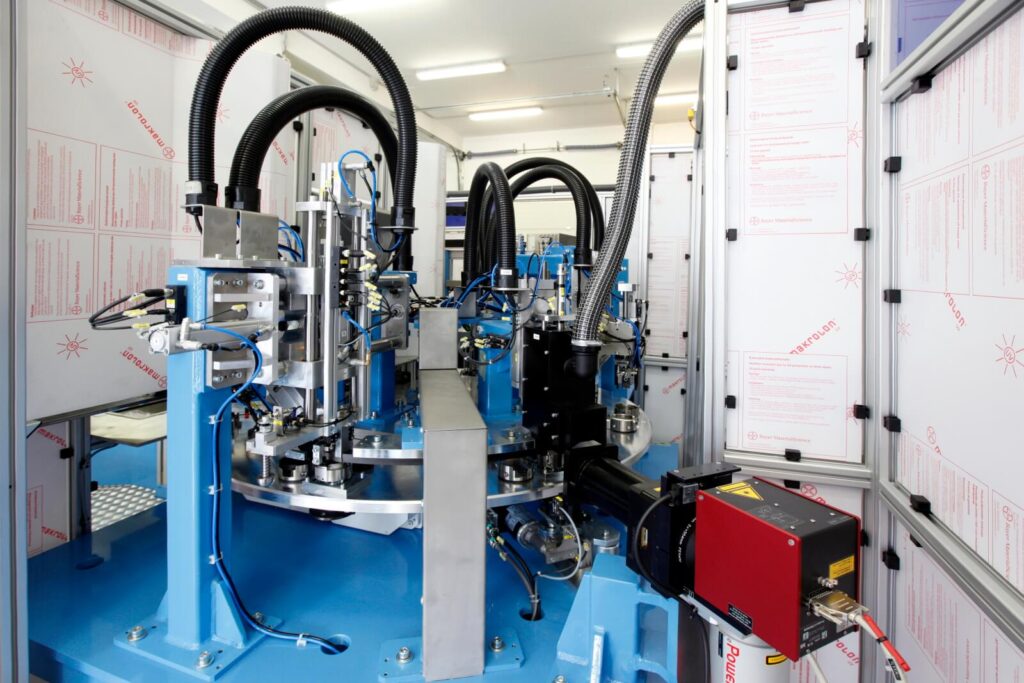

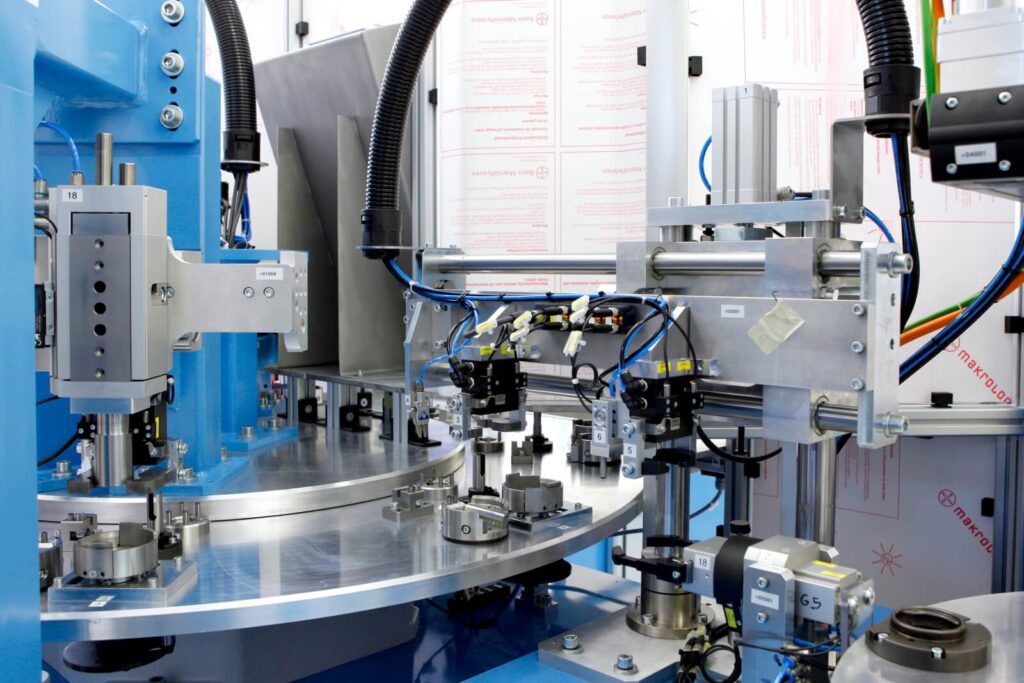

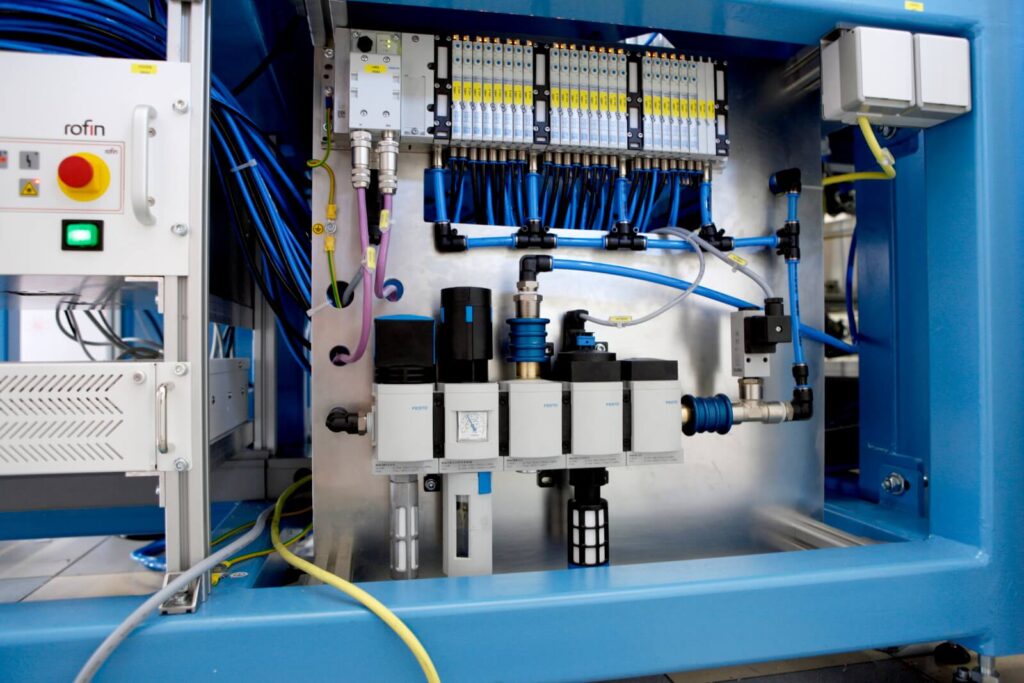

Our customer’s goal was to create a system for assembling and testing tank caps that would be as compact and tamper-proof as possible and would check the quality of the parts produced. In addition, it was one of the first plants in which the 2nd Generation Panel from Siemens was implemented.

Intensive mechanical design meetings were held in the run-up to the project. During these discussions, both the mechanical design and the electrical design were defined. This also allowed program-specific topics to be defined in advance. The advantage was a better quality of the specification documents for electrical engineering and programming.

During the plant implementation, the main focus was on ongoing pre-testing. In order to minimize the error rate at the start of production, a test setup was created on site that allowed for preliminary material tests, as well as optimizations based on these tests. This made it possible to continuously fine-tune the desired final quality and deliver ideal results to the OEM in time for the start of production.

Since the successful and smooth commissioning, the plant has been continuously expanded with additional functions so that new types can also be produced. As a regional and quickly available partner, we were able to offer our customer complete support with project management, engineering and programming from a single source. A service that was very well received!

At AUTFORCE, we specialise in testing systems and industrial software. Get in touch with us. Together we will find the best solution for your project!

Christian Hanbauer

Expert Test Systems

+43 (664) 88 71 02 50

[email protected]

Get a non-binding initial assessment now: