Quick implementation

Thanks to a well-established partner network and a dedicated project team, the system was tested for the first time just four months after the order was received and was fully handed over to the customer after six months.

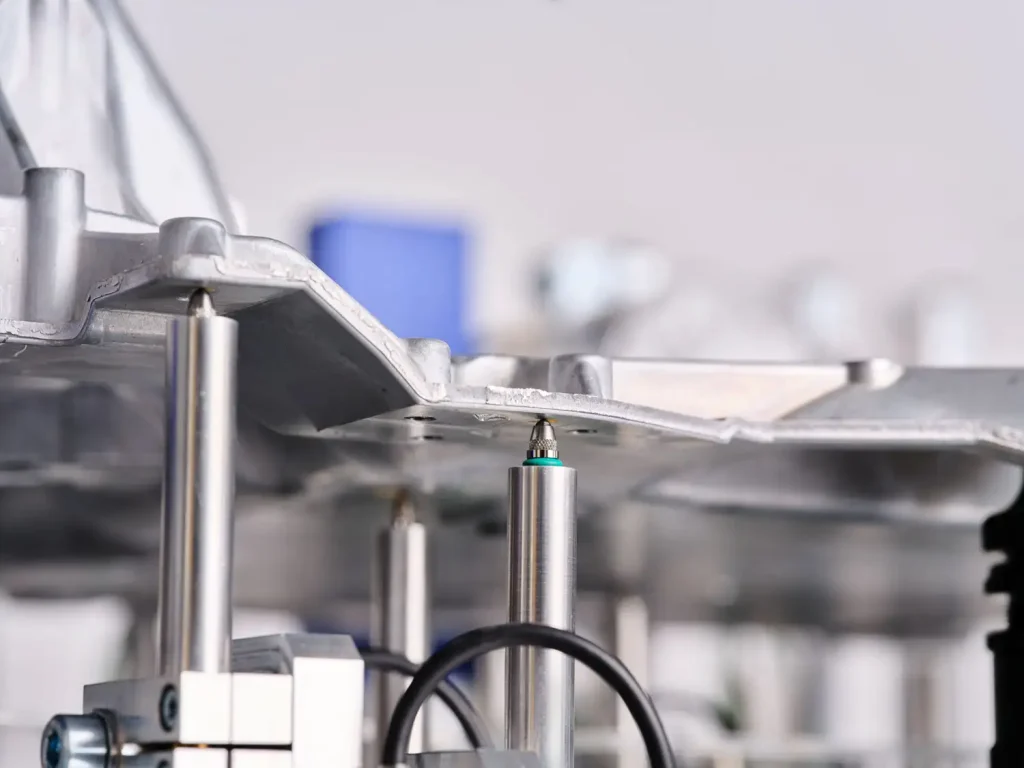

What can be done when each individual component is particularly costly to manufacture and errors in assembly can quickly lead to further costs? AUTFORCE has developed a suitable solution for a leading manufacturer of aluminum die-cast components: a testing system with two coordinated stations, a measuring station and an assembly station.

At the first station (measuring station or inspection fixture) each component is carefully checked for dimensional accuracy and completeness. Only then does assembly take place, during which bolts, screws, and brackets are added. Finally, the component is checked once again to ensure that the finished assembly

The progress of the project is particularly impressive: initial tests were carried out just four months after the order was received. After only six months, the entire system was ready for use and was delivered to the customer. This was made possible by a proven partner network, flexibility within the project team, and close coordination across all project phases.

Contact us

Each aluminum die-cast part undergoes a standardized three-step process:

The double check ensures that only flawless parts are assembled and passed on, and that no deformations occur during assembly. Each component can be clearly traced via a data matrix code (DMC).

Before assembly, each component is checked for dimensional accuracy and completeness.

The assembly process combines automated procedures with specific manual steps.

The final inspection ensures the quality of the assembled component. Only fully tested components are released for further processing.

At AUTFORCE, we specialise in testing systems and industrial software. Get in touch with us. Together we will find the best solution for your project!

Christian Hanbauer

Expert Test Systems

+43 (664) 88 71 02 50

[email protected]

Get a non-binding initial assessment now: