EN

touch

For our customer in the energy technology industry, we implemented an automated testing system for quality control of insulated winding conductors used in transformers. The aim was to reliably detect damage to the insulation and thus ensure the quality of the subsequent windings.

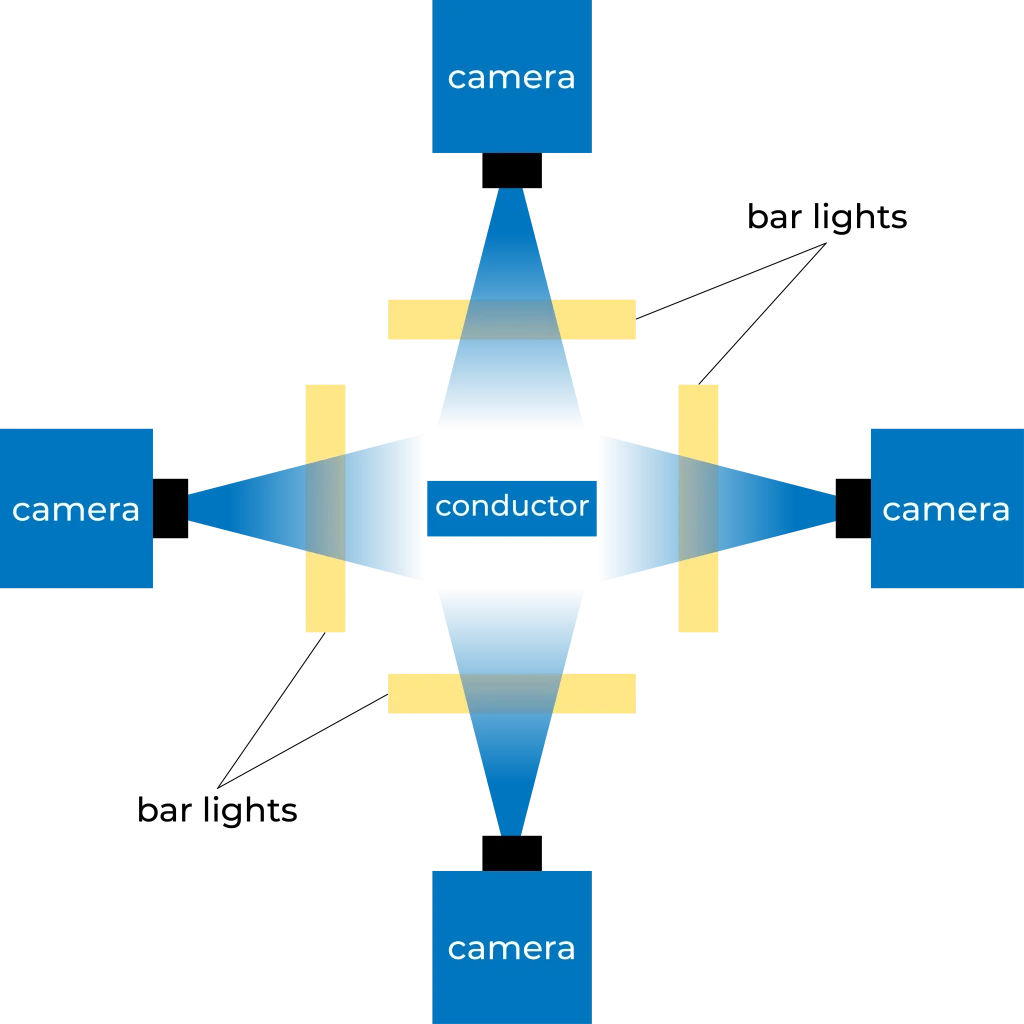

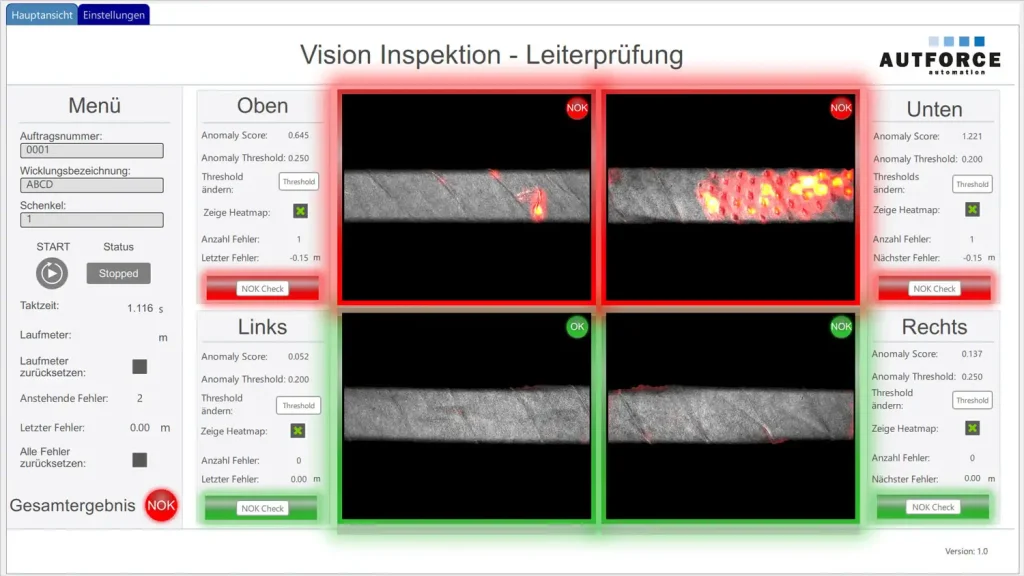

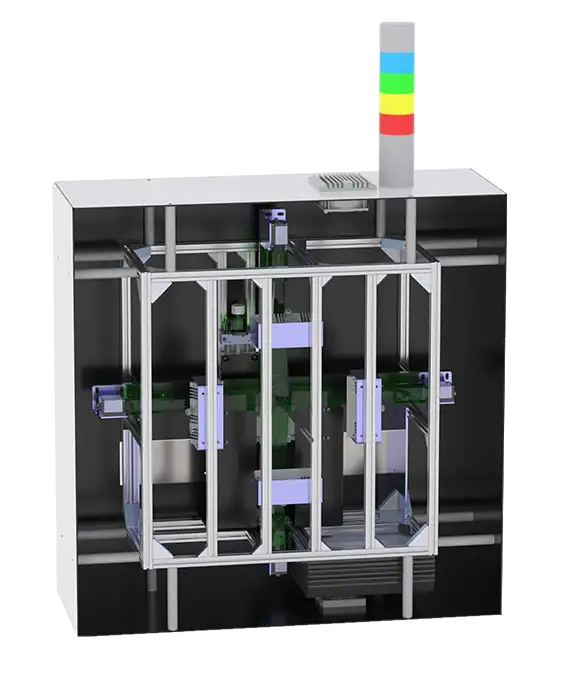

The inspection system is designed as a stand-alone unit with its own control system and can be flexibly integrated into existing production lines. All sides of the conductor are captured by a camera system with four line scan cameras arranged in perspective. AI-supported anomaly detection automatically identifies even the smallest damage. When defects are detected, the system stops the feed, visually displays the defect, and allows the operator to check it directly.

The testing system guides each insulated winding conductor through a compact camera housing, where four high-resolution cameras capture images of all sides of the conductor. The image data is evaluated in real time: an AI-supported system automatically detects deviations and damage, even if they are very small or difficult to see.

As soon as a defect is detected, the system stops feeding and shows the operator the exact position of the defect on a user interface. The operator can then check the conductor and either approve it or reject it. In addition, all images and test results are stored for complete traceability.

Thanks to the modular design, flexible integration into existing production lines, and reliable AI detection, the customer was able to significantly optimize the quality assurance of its winding processes and considerably reduce the amount of manual inspection work required.

More about optical quality control

At AUTFORCE, we specialise in testing systems and industrial software. Get in touch with us. Together we will find the best solution for your task!

Christian Hanbauer

Expert Test Systems

+43 (664) 88 71 02 50

[email protected]

Get a non-binding initial assessment now: